"A decade of progress in a year; the humanoid robot era is here, and it's accelerating with astonishing speed and breathtaking developments." - Futurist Jim Carroll

(Futurist Jim Carroll is writing a series on 30 Megatrends, which he first outlined in his book Dancing in the Rain: How Bold Leaders Grow Stronger in Stormy Times. The trends were shared in the book as a way of demonstrating that, despite any period of economic volatility, there is always long-term opportunity to be found. The book is now in print - learn more at dancing.jimcarroll.com)

The humanoid robot industry is accelerating due to a convergence of advanced AI, collapsing hardware costs, and massive new investment. This is moving humanoids from science fiction to industrial reality, with deployments scaling in factories to address global labor shortages. The next wave will expand into healthcare and elder care, bringing the long-term vision of domestic assistance closer to reality.

What does it mean? Well, for one thing, my family keeps telling me that I'll need to have some sort of hobby when I eventually retire. So I've settled on the idea that within 5 years, I'll probably have a humanoid robot in the house that I can train and work with. I've been telling the guys on the golf course that I'll be showing up with my robot caddy at some point - it will carry my bag, and perhaps offer up some golf advice. I made a short little video imagining this.

Most of them were not amused. My wife, in particular, is not excited by the idea and has registered an emphatic NO. I can see this is going to take some work.

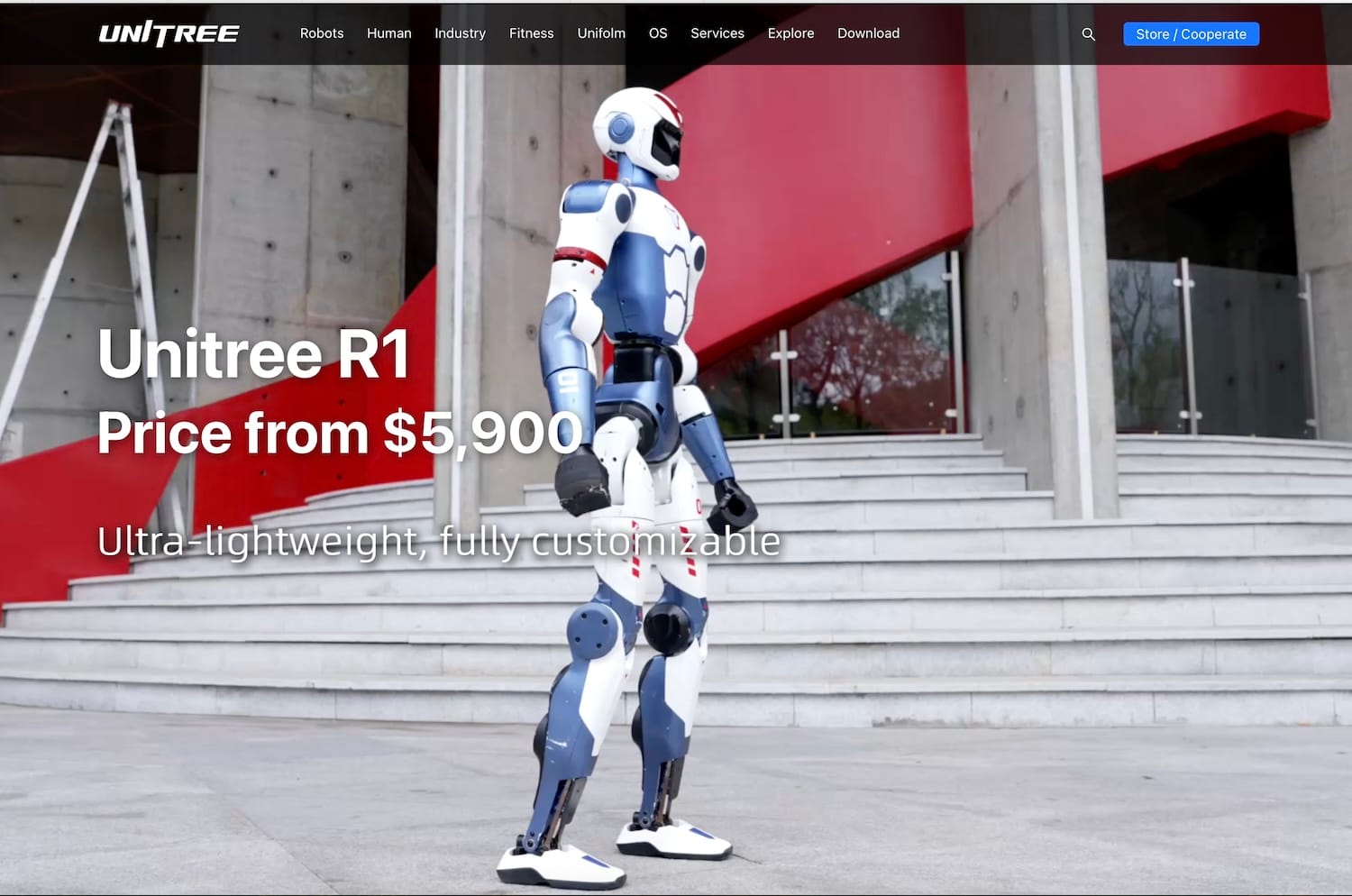

That said, the cost for these fascinating little devices is fast approaching the PC-cost collapse curve, with the Chinese-made Unitree R1 now available for $5,900 US. Give it a few years, and you'll be able to grab one for $999.

This trend is bringing us closer and closer to the reality of my favorite predictive TV show!

So what's up? We are clearly at the Humanoid Robot Inflection Point:

We stand at a historic inflection point in humanoid robotics, driven by the powerful convergence of exponential AI advances, unprecedented capital investment, revolutionary training technologies, and rapidly falling hardware costs—all unfolding within a distinct geopolitical landscape that will shape the future of work.

There's a full PDF right here if you want to dig in further.

So let's start here. Why is this now occurring? Hasn't the technology world and science fiction fans dreamed of such a future for a long time? Because essentially, four key forces are coming together all at once:

- Exponential AI Advances: Vision-language and reinforcement learning models are creating a functional "brain" enabling robots to understand, reason, and act in complex environments.

- A Capital 'Supercycle': Strategic investments from technology giants signal confidence in humanoids as the next major computing platform.

- Digital Training Revolution: "Digital gyms" enable accelerated, low-cost, and scalable training, drastically reducing development timelines.

- Collapsing Cost Curve: Economies of scale in adjacent industries like electric vehicles and consumer electronics are making mass production economically viable for the first time.

All of this means that what we thought was far away is suddenly... at our doorstep.

This trend is also unfolding worldwide, but in fundamentally different ways:

- United States: AI-First: Leading in AI and software development with a robust venture capital ecosystem that attracts 70% of global investment in the sector.

- China: Hardware-First. Leveraging its formidable manufacturing base and state-backed industrial policy to achieve dominance in the hardware of the systems.

- Europe: Regulation-First. Emphasizing a human-centric approach that prioritizes safety, ethics, and legal clarity, potentially positioning the EU as the global standard-setter.

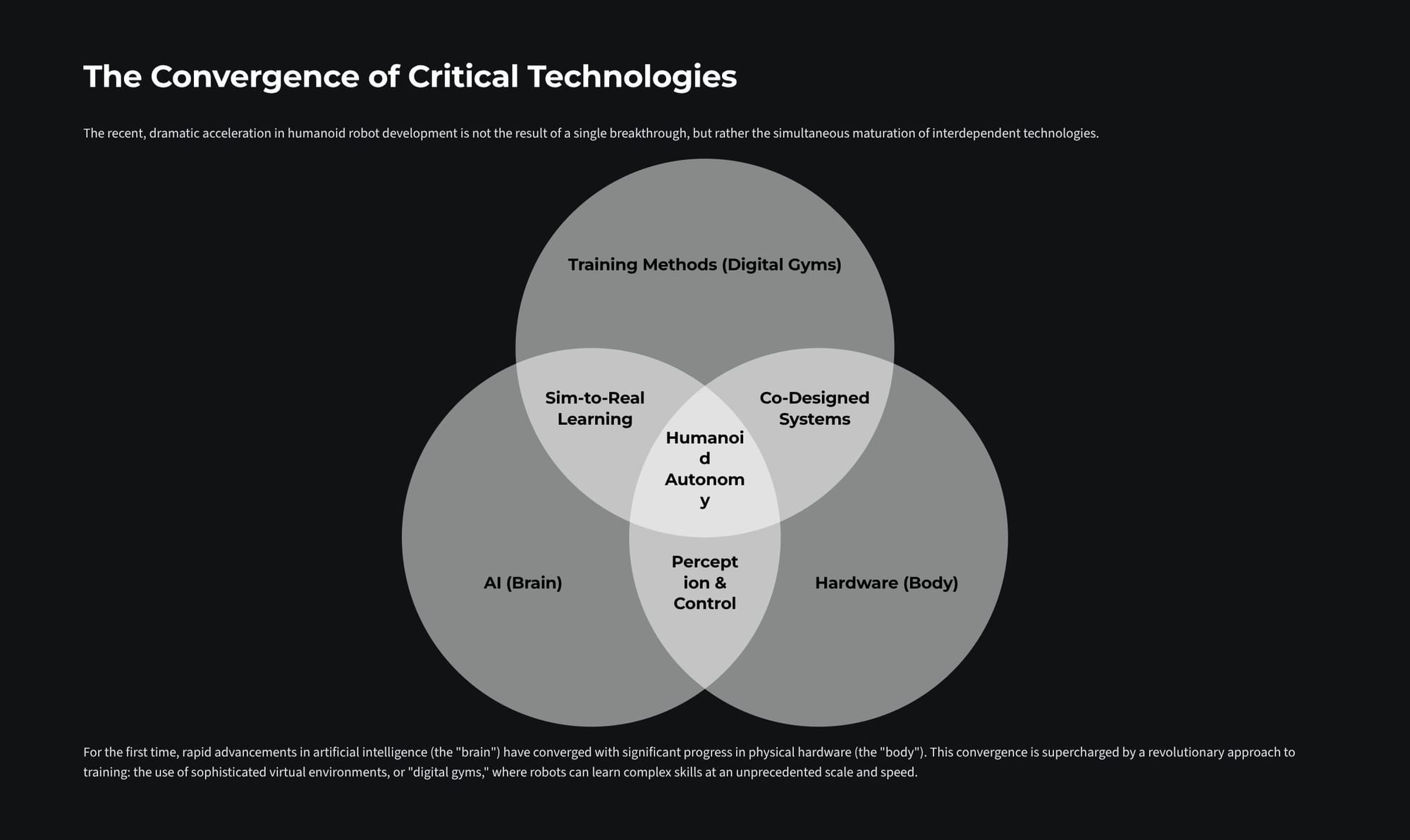

This is a big and fast-moving trend, so let's first outline the convergence of the critical technologies that are making all of this possible.

To start, the recent, dramatic acceleration in humanoid robot development is not the result of a single breakthrough, but rather the simultaneous maturation of interdependent technologies. For the first time, rapid advancements in artificial intelligence (the "brain") have converged with significant progress in physical hardware (the "body"). This convergence is supercharged by a revolutionary approach to training: the use of sophisticated virtual environments, or "digital gyms," where robots can learn complex skills at an unprecedented scale and speed.

At the heart of it all, of course, is the 'software brain'. We are seeing the evolution of the robot's control system from a rigid, logic-based program to an adaptive, learning-based intelligence at a rapid pace.

Why is that? Early robots were limited to executing pre-programmed, scripted routines - each step, each arm movement was tightly programmed, limiting what was possible. But now, the current generation of humanoids represents a paradigm shift, powered by the same generative AI technologies that have revolutionized natural language and image generation. Vision-Language-Action (VLA) models are giving humanoids a rudimentary form of understanding and reasoning. Instead of being programmed with explicit instructions, a robot can now be given a high-level command in natural language, such as "put the coffee cup on the counter."

That's a pretty profound change.

Second, we are seeing the arrival of the 'digital gym.'

Training a physical robot through real-world trial and error is prohibitively slow, expensive, and dangerous. The solution to this bottleneck has been the development of these "digital gyms"—high-fidelity, physics-based simulation environments where robots can be trained at a massive scale. In my case, I'll film myself carrying a golf bag, and taking out a club - and will then upload the visual to my robot-caddy, providing it with the insight into the actions to undertake.

Third are advancements with the "electric body", which involves advancements in actuation, sensing, and dexterity. The new robots have the moves!

And so while the AI brain has undergone a revolution, the physical body has undergone a critical evolution. A key enabling technology has been the industry-wide shift from hydraulic to electric actuation. The original Boston Dynamics Atlas robot, which you might have seen online, was hydraulic, providing immense power but also complexity and inefficiency. The new generation, including the all-electric Atlas, Tesla's Optimus, and Figure's Figure 02, exclusively uses electric actuators, making the robots safer, quieter, and more energy-efficient. Think of it as a 'Robot 2.0.'

This includes several key hardware advancements:

- Sensor Fusion: Modern humanoids achieve robust perception and balance through sophisticated sensor fusion, integrating data from 3D LiDAR, multiple RGB cameras, Inertial Measurement Units (IMUs), and force/torque sensors. They can see, move, balance, and sense - letting them navigate raised greens, tee boxes, and perhaps even bunkers.

- Battery Technology: Significant improvements with systems like Figure's F03 battery providing five-hour peak performance. Advanced lithium-ion systems now reach energy densities of 350-500 Wh/kg, enabling practical all-day operation. They can last a long time! A four-hour round of golf!

- Dexterous Manipulation: While human hands have 27 degrees of freedom (DoF), current robotic hands have around 16-20 DoF. Sanctuary AI's Phoenix boasts hands with 20 DoF, while Figure 02's hands have 16 DoF, enabling complex manipulation tasks. They can grasp things more easily and do things with the things they grasp! Like golf clubs!

A lot of this is being accelerated by the catalyst that is open source.

Open-source software, particularly the Robot Operating System (ROS), has become a de facto standard, providing a common framework of libraries and tools for developers. This prevents teams from having to "reinvent the wheel" for basic functions and allows them to focus on higher-level capabilities. Frameworks like MoveIt, integrated with ROS, allow for complex manipulation using standardized interfaces.

More recently, this open-source spirit is extending to hardware. Projects like the Berkeley Humanoid Lite are making designs for capable, 3D-printable robots publicly available, while platforms like Pollen Robotics' Reachy and ROBOTIS OP3 offer fully open-source hardware and software stacks. This democratizes access to humanoid robotics, lowering the traditionally high barrier to entry for researchers, students, and startups.

Want a robot? Mechanically inclined? Have a 3d printer? Download the plans and get going!

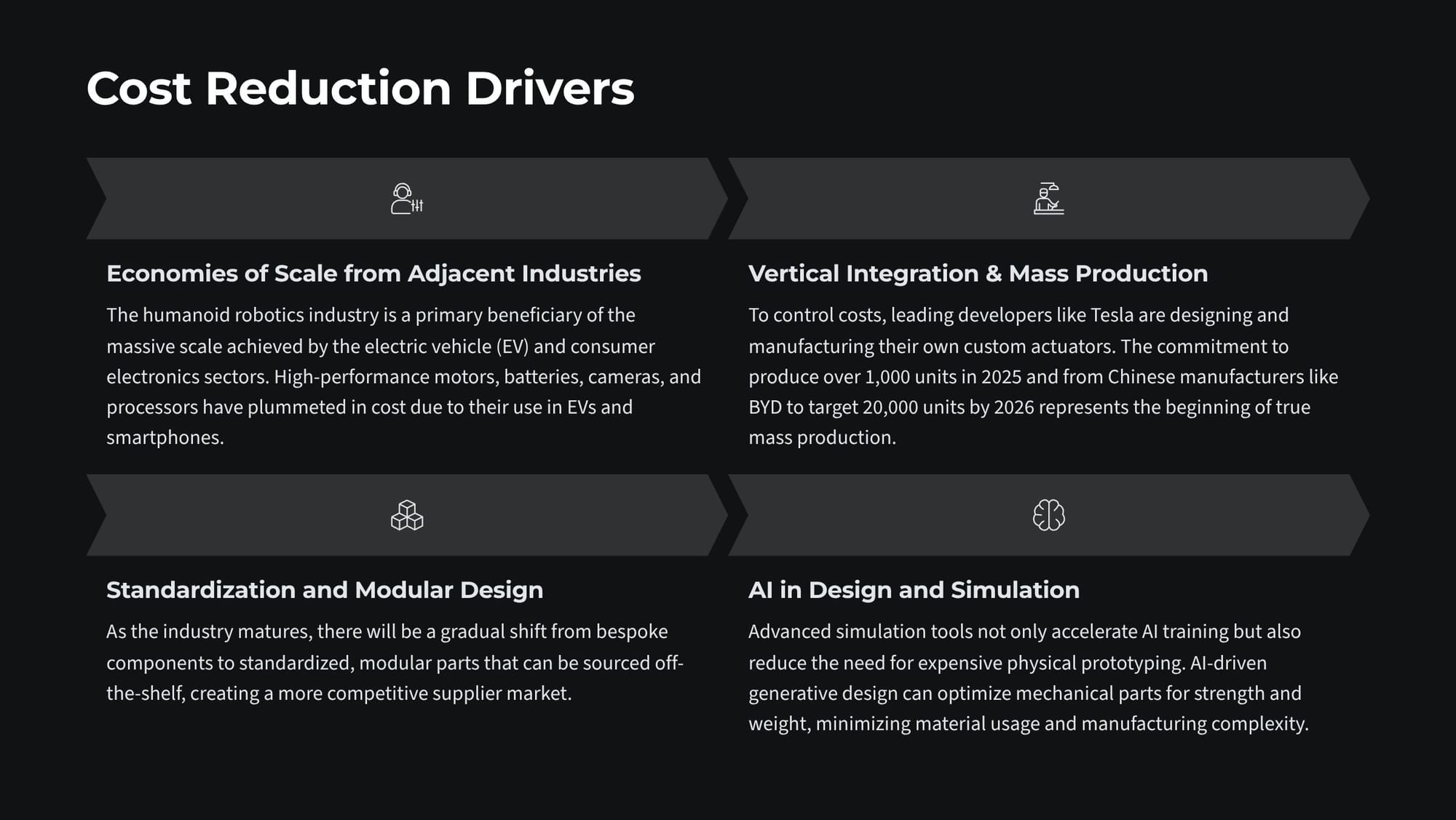

Add it all together, and the cost for an average robot will come down dramatically in the years to come. Driving it are the typical trends involving tech:

- Economies of Scale from Adjacent Industries: The humanoid robotics industry is a primary beneficiary of the massive scale achieved by the electric vehicle (EV) and consumer electronics sectors. High-performance motors, batteries, cameras, and processors have plummeted in cost due to their use in EVs and smartphones.

- Vertical Integration & Mass Production: To control costs, leading developers like Tesla are designing and manufacturing their custom actuators. The commitment to produce over 1,000 units in 2025 and from Chinese manufacturers like BYD to target 20,000 units by 2026 represents the beginning of true mass production.

- Standardization and Modular Design: As the industry matures, there will be a gradual shift from bespoke components to standardized, modular parts that can be sourced off-the-shelf, creating a more competitive supplier market.

- AI in Design and Simulation: Advanced simulation tools not only accelerate AI training but also reduce the need for expensive physical prototyping. AI-driven generative design can optimize mechanical parts for strength and weight, minimizing material usage and manufacturing complexity.

So, how will we see these interesting little devices come into our world? We know it is going to happen - the big will is how it will happen!

The transition of humanoid robots into the workforce will not be a sudden event but a phased integration, beginning in highly structured environments and gradually expanding into more complex and dynamic domains.

The initial adoption is dictated by a pragmatic calculus: humanoids will first be deployed where the tasks are dull, dirty, or dangerous—roles that companies struggle to fill and that humans are often glad to relinquish.

The most immediate and commercially viable market for humanoid robots is in industrial settings. Factories and warehouses are structured, predictable environments that mitigate many of the current challenges of autonomous navigation and interaction. The tasks are often repetitive and physically demanding, leading to high worker turnover and risk of injury, creating a clear and compelling business case for automation.

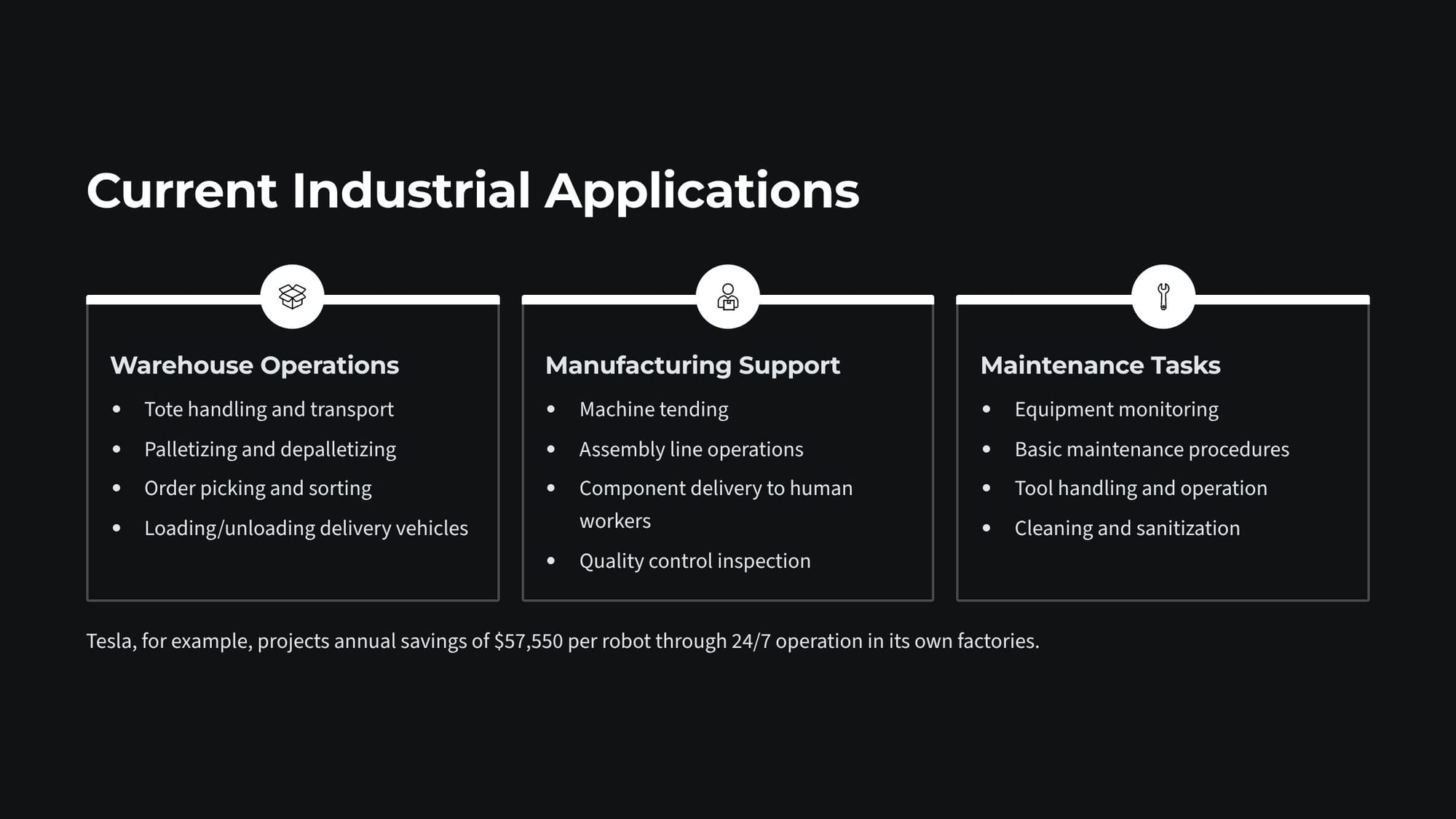

This includes these applications in use today:

Warehouse Operations

- Tote handling and transport

- Palletizing and depalletizing

- Order picking and sorting

- Loading/unloading delivery vehicles

Manufacturing Support

- Machine tending

- Assembly line operations

- Component delivery to human workers

- Quality control inspection

Maintenance Tasks

- Equipment monitoring

- Basic maintenance procedures

- Tool handling and operation

- Cleaning and sanitization

Is this stuff real? Yes! Tesla, for example, projects annual savings of $57,550 per robot through 24/7 operation in its factories.

As the technology matures and costs decline, the next wave of applications will be in semi-structured, public-facing commercial environments - rural, hospitality, and healthcare support.. In these roles, humanoids will augment human staff, handling routine tasks to free up employees for more complex, customer-facing interactions.

This could include:

- Clinical Logistics: Robots like Diligent Robotics' Moxi are already being deployed to transport lab samples and deliver medications, allowing skilled nurses to spend more time on direct patient care.

- Elder Care: A significant opportunity lies in elder care, particularly in countries with aging populations like Japan. Humanoids can provide companionship, offer medication reminders, and assist with daily activities in managed care facilities.

- Rehabilitation: Companies like China's Fourier Intelligence are specifically developing robots like the GR-1 for medical rehabilitation and therapy support, while NAO robots assist with patient engagement.

A key point: in healthcare, humanoids are not positioned to replace doctors or nurses, but to alleviate the immense logistical burden on clinical staff.

And finally, there are the High-Stakes Deployment categories - involving hazardous environments, disaster response, and space. (A compelling long-term market for humanoids exists in applications where sending a human is either too dangerous or impossible.) In these scenarios, the high cost of the robot is easily justified by the infinite cost of a human life.

This would include:

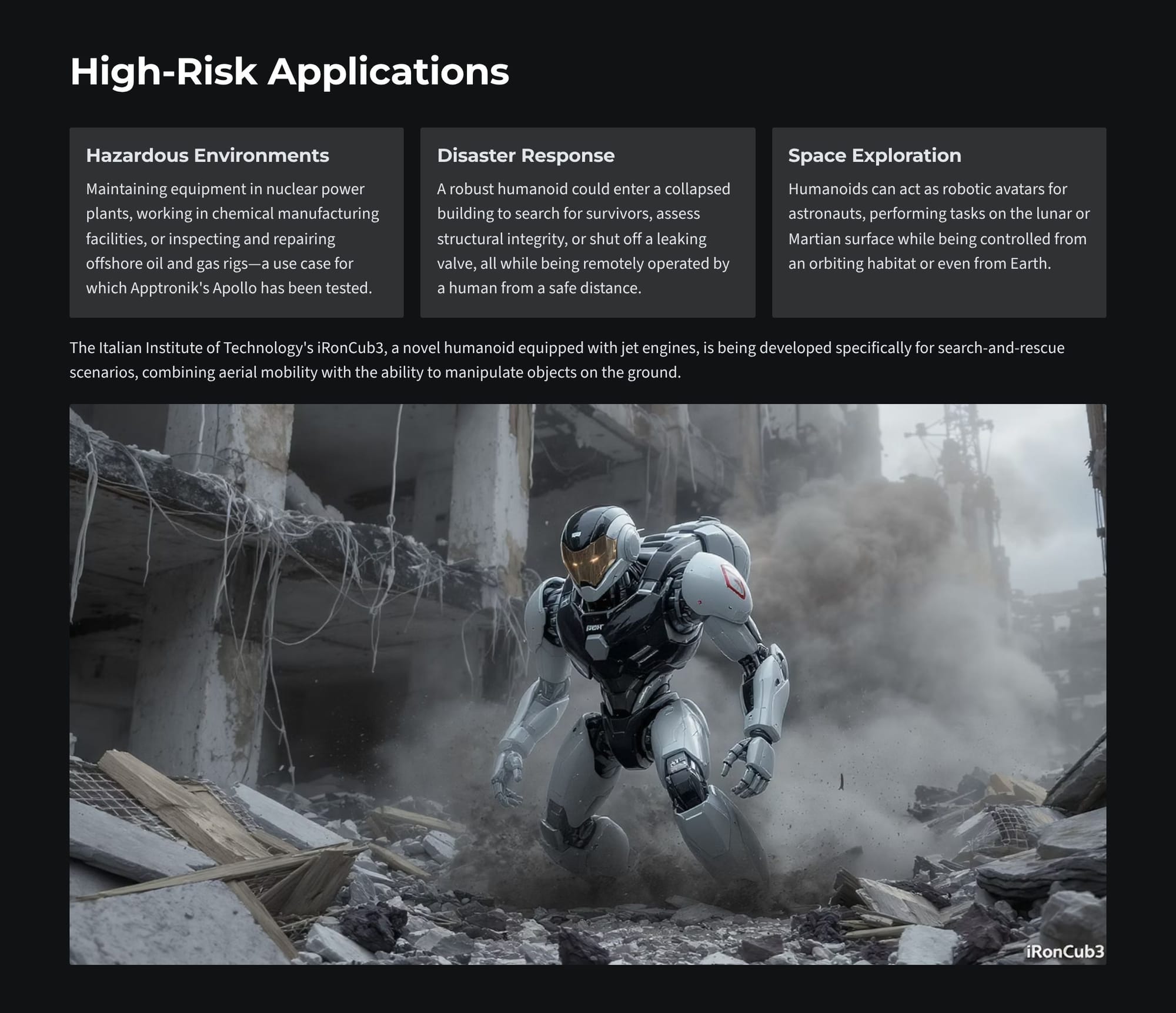

- Hazardous Environments: Maintaining equipment in nuclear power plants, working in chemical manufacturing facilities, or inspecting and repairing offshore oil and gas rigs—a use case for which Apptronik's Apollo has been tested.

- Disaster Response: A robust humanoid could enter a collapsed building to search for survivors, assess structural integrity, or shut off a leaking valve, all while being remotely operated by a human from a safe distance.

- Space Exploration: Humanoids can act as robotic avatars for astronauts, performing tasks on the lunar or Martian surface while being controlled from an orbiting habitat or even from Earth.

The Italian Institute of Technology's iRonCub3, a novel humanoid equipped with jet engines, is being developed specifically for search-and-rescue scenarios, combining aerial mobility with the ability to manipulate objects on the ground.

So what about the big, unstructured future, involving the typical home?

The primary reason for the difficulty of domestic robotics lies in the fundamental difference between a factory and a home. A factory is a structured environment. A home is the epitome of an unstructured environment: dynamic, cluttered, and infinitely variable. Tasks that seem simple to humans, such as "folding laundry" or "emptying the dishwasher," are problems of immense complexity for a robot. These tasks require a profound level of perception, fine motor control, and common-sense reasoning that is far beyond current systems.

I'm not quite sure where golf caddying stands on that list!

And the fact is, there are very real technical limitations for domestic deployment:

- Dexterity Gap: Today's humanoid hands have only around 16 degrees of freedom compared to 27 in human hands, limiting their ability to manipulate soft or fragile objects common in homes. My golf robot is going to be kind of clunky at the start.

- Battery Constraints: Current battery technology limits operation to 2-5 hours before requiring a lengthy recharge, which is incompatible with all-day household assistance needs. I don't need my robot to die on the 12th tee!

- Environmental Complexity: Homes contain thousands of unique objects in constantly changing arrangements, creating a perception and navigation challenge far beyond current AI capabilities. The bunker might prove to be an insurmountable challenge.

- Task Generalization: The diversity of household tasks requires a level of generalized intelligence and adaptability that exceeds the capabilities of today's specialized AI systems. Finding my slice in the woods might be a big problem!

And beyond that, there is a real question as to whether it will ever even be economically viable. Even if the technical and safety challenges could be overcome, the economic viability of a general-purpose domestic humanoid is questionable in the near to medium term. While costs are falling, a consumer robot would still represent a major household purchase.

Even with projected cost reductions to $20,000-$30,000 by 2030, the value proposition for the average consumer is unclear. Most households have already automated specific domestic tasks with far cheaper, single-purpose devices. A general-purpose humanoid would need to perform a wide range of tasks significantly better than these specialized appliances to justify its high cost.

Morgan Stanley's market forecast reflects this reality, projecting that by 2050, 90% of humanoids will be used for industrial and commercial purposes, with only a small fraction finding their way into homes.

So what about Rosie the Robot?

The long-held vision of a domestic humanoid assistant remains a distant dream rather than a near-term product.

- The immense technical challenges of operating in unstructured home environments

- Critical safety and regulatory hurdles

- Significant economic barriers to consumer adoption

While pilot programs in semi-structured settings like elder care facilities will emerge, widespread consumer adoption is not anticipated within the decade. The primary focus for the next decade will be the transformation of the global workforce and industrial landscape.

Even so, I am not deterred!

Fore!

Futurist Jim Carroll expects to have a bit of pushback when he arrives at the golf course with his humanoid robot.