"The most valuable part of a modern manufacturing operation is the part you can't see: the algorithms that optimize flow, the data that predicts failure, and the agility that makes the entire process intelligent." - Futurist Jim Carroll

In September 2025, the headwinds are severe, and the path forward seems shrouded in fog. We’re living through one of the most volatile and unpredictable periods in recent memory. With that being the case, I am writing this new series, The Way Forward: A Trends and Transformation Series, taking a look at the trends redefining industries, and actionable strategies organizations must pursue to align to these realities. The entire series will be found at forward.jimcarroll.com

This single idea captures the profound shift underway in manufacturing.

Success is no longer measured by physical output alone, but by the intelligence embedded within the entire production process. That intelligence allows for flexible manufacturing, advanced product development, sophisticated production monitoring, and more.

For many Small and Medium-sized Enterprises (SMEs), however, accessing this new world of intelligent manufacturing can seem daunting. With that in mind - and given the vast number of manufacturing events, conferences, and leadership meetings I've spoken at, it's a good time to summarize the critical trends transforming the industry, the significant barriers faced by SMEs, real-world examples of success, and an actionable path forward to navigate the future.

The Landscape: 10 Trends Redefining the Future of Manufacturing

To navigate the future, you must first accept the new reality. These are not distant, abstract concepts; they are the active forces reshaping our world today. I've covered these relentlessly on stage - they are often referred to as the trends of Factory 2.0 or Factory 4.0 or whatever number you want to give them!

- Compressed Innovation Cycles & Agility: Product lifecycles are collapsing, demanding faster innovation and time-to-market. The future belongs to organizations that are agile, flexible, and can pivot quickly, embracing "the velocity of continuous reinvention".

- AI-Powered Automation & Robotics: Artificial intelligence is revolutionizing the factory floor. This includes machine vision for quality control, predictive maintenance to reduce downtime, and collaborative robots (cobots) that work alongside humans to boost efficiency and safety.

- Mass Customization & Personalization: The era of mass production is yielding to mass customization. Flexible manufacturing systems, powered by new technologies, are enabling the personalized creation of products at scale.

- Additive Manufacturing (3D Printing): 3D printing has moved from a "far-fetched crazy idea" to a mainstream technology. It is a cornerstone of rapid prototyping and iterative design, allowing companies to go from blueprint to physical product in hours.

- The Industrial Internet of Things (IIoT): Billions of sensors are being layered throughout facilities, creating "smart factories." This massive connectivity allows for real-time data exchange, automated communication between machines, predictive diagnostics, and enhanced supply chain tracking.

- Digital Twin Technology: This involves creating dynamic, virtual replicas of physical products, processes, or entire factories. Continuously updated with real-time IoT data, digital twins serve as a risk-free environment to test, simulate, and optimize operations before committing physical resources.

- Supply Chain Reinvention & Resilience: Globalization is changing, leading to "The Great Decoupling."Companies are shifting from "just-in-time" to "just-in-case" operations, prioritizing resilience through strategies like reshoring and "friendshoring".

- Accelerated Materials Science: The discovery and creation of new materials are happening faster than ever. Advanced composites, nanomaterials, and smart materials are expanding the palette for manufacturers, enabling the creation of products with precisely tailored properties.

- Advanced Skills: As manufacturing becomes more complex, the nature of work is changing. Routine manual skills are being replaced by the need for advanced capabilities in robotics, data analytics, and complex problem-solving. An estimated 1.9 million manufacturing jobs are at risk of going unfilled due to this skills gap.

- Data-Driven Decision Making: The fusion of AI and Big Data analytics allows manufacturers to generate predictive insights for everything from quality control to supply chain optimization. Every customer choice becomes a data point that can be analyzed to identify market trends and optimize future offerings.

The Great Divide: Why SMEs Are Facing a Crisis of Catch-Up

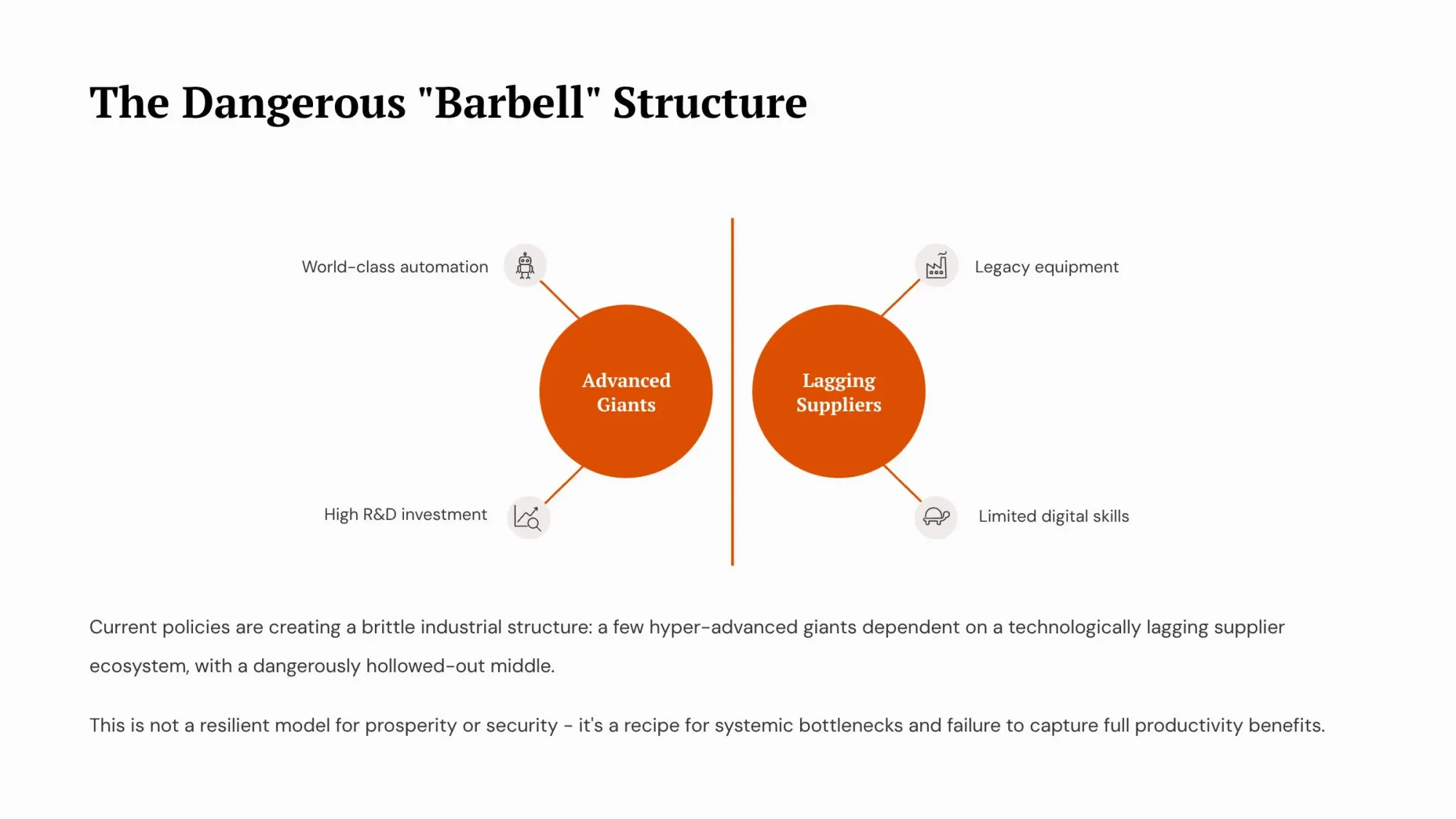

The modern manufacturing landscape is defined by a stark dichotomy, creating a 'barbell economy' within the sector. I wrote about that in another post.

At one end are large corporations with the capital and foresight to invest heavily in advanced technologies. At the other, thinner end, are the vast majority of Small and Medium-sized Enterprises (SMEs), which risk being left behind. This growing chasm poses a systemic risk to the competitiveness of our entire manufacturing ecosystem.

In the US, small and medium-sized manufacturers (SMMs), comprising over 95% of the industrial base, are lagging in technology adoption. A 2022 survey showed that while over 75% recognized smart technology's importance, only half were willing to invest. Similarly, in Europe, where SMEs represent 99% of all registered companies, only about 5% of SMEs have engaged with AI technology. This slow adoption means SMEs are missing out on critical productivity gains, threatening their long-term viability.

Three core barriers are holding them back:

- Financial Constraints: The most cited barrier is the dual challenge of high upfront capital costs and uncertain Return on Investment (ROI). For SMEs with tight margins, investing in industrial robotics or IIoT networks can be a non-starter. This creates a vicious cycle: without investment, they can't improve productivity to generate the capital needed for future investments. Without productivity, they can't compete and can't make enough money to invest. Boom.

- The Skills and Knowledge Deficit: A profound human capital gap remains. There is a shortage of skilled workers to operate and maintain advanced systems. A 2024 report noted that 46% of US manufacturers say they lack the skilled workforce needed to compete. This extends to the executive level, where many SMEs lack the internal expertise to assess technologies and build a business case for them.

- Strategic and Organizational Hurdles: Many SMEs lack a formal, structured approach to technology adoption. Over half of UK SME manufacturers admit that technology is not an integrated part of their future vision. This leads to ad-hoc purchases and wasted investment. Furthermore, integrating new technologies with legacy systems in factories that are, on average, 25 years old is a significant obstacle.

The primary hurdle is not just the cost of entry, but the development of an organizational capacity for continuous learning and adaptation. The barbell economy is a gap in adaptive capacity - it's a failure in innovation - and it's a setback with initiative.

An Actionable Playbook for SME Modernization

For SME leaders daunted by these barriers, the path forward requires initiative!

I'd suggest this:

1. De-Risk the Technology Leap: From Big Bets to Smart Steps

The perception of technology adoption as a single, high-risk expenditure is a significant psychological barrier. The key is to break the process into manageable, small base steps - subscribe to my 'think big, start small, scale fast' approach, with an emphasis on the 'small.'

- Adopt a phased approach: Resist the allure of "technology for technology's sake." A successful transformation begins with a plan. Develop a digital roadmap that identifies your core business challenges—low productivity, quality control issues, long lead times—and then prioritizes the technological solutions that directly solve those problems.

- Do more pilot projects: Instead of a factory-wide overhaul, start small to de-risk the investment. Test a single collaborative robot on one assembly step or an IIoT sensor kit on a critical machine. This "fail fast, learn faster"methodology minimizes financial exposure while building internal expertise and confidence.

- Start with data: A common misstep is buying data-generating equipment before having systems in place to manage the data. A more logical starting point is implementing a modern Enterprise Resource Planning (ERP) system to create a single source of truth for your entire operation. You need not be a huge organization to invest in an SAP or other ERP system!

2. Start Closing the Skills Gap

For SMEs that cannot compete with large corporations on salary, closing the skills gap requires creative, collaborative strategies.

- Leverage Academic and Research Partnerships: Local universities and public research institutions are invaluable resources. In Germany, for example, the Fraunhofer-Gesellschaft acts as an external, on-demand R&D department for SMEs, providing direct access to world-class researchers and state-of-the-art equipment.

- Utilize Work Placement Programs: Talk to your local community college - they might have the people you need! Hiring students for co-op terms or internships is a highly effective, low-cost strategy for injecting new skills and fresh perspectives into your organization.

- Focus on Upskilling the Existing Workforce: Investing in the skills of current employees is critical. Move towards a model of continuous learning, starting with regular skills assessments to identify and anticipate future needs.

3. Play to Your Strengths

The most profound transformation required is cultural. SMEs must shift from a reactive, operations-focused mindset to one that nurtures new ideas and embraces strategic innovation.

- Lead differently: Innovation culture is driven from the top down. Leaders must dedicate a significant portion of their own time—some experts suggest 20-40%—to actively working on innovation initiatives. They must empower their teams with the autonomy to experiment.

- Empower Small, Agile Teams: Use your small size as an advantage. Create cross-functional teams with the resources and psychological safety to experiment in a "fail fast" environment where setbacks are viewed as valuable learning opportunities.

- Implement Lean Innovation Processes: Adopt leaner processes specifically for innovation. A simple but powerful tool is giving an innovation team a company credit card to bypass slow procurement for small-scale experiments - to let people play!

Putting Strategy into Action: Real-World Examples of Success

I did a little bit of research using Google Gemini, and there are countless stories of successful SME innovation in the world of Factory 4.0. These strategies are not theoretical. A growing number of SMEs are successfully bridging the chasm, providing a practical blueprint for others to follow.

- ZIMM GmbH (Austria): This SME manufacturer of spindle lift gears needed to increase production flexibility and efficiency for unmanned shifts.20 By implementing a modular manufacturing cell with a KUKA loading robot, ZIMM automated the physically demanding task of loading heavy metal parts. The outcome: The company can now run unmanned shifts, which has significantly increased its competitiveness, while employees have been relieved of heavy physical work and reassigned to more valuable tasks.20

- Trenton Pressing (Georgia, USA): This manufacturer was struggling with a high scrap rate and an on-time delivery rate of only 60%. They partnered with the Georgia Manufacturing Extension Partnership (GAMEP) to implement a series of process improvements and technology upgrades. The outcome: Trenton Pressing dramatically reduced its scrap rate by 60% and improved on-time delivery from 60% to over 90%, setting the company up for sustained growth.

- Rohleder (Germany): A medium-sized, family-owned textile manufacturer, Rohleder's high-mix, low-volume production model made adopting standard automation difficult. They took a measured, strategic approach, partnering with local universities to analyze machine data and improve weaving efficiency. They also selectively integrated AI tools like ChatGPT in their sales department to improve customer communication. The outcome:The university collaboration led to a 20% increase in weaving productivity and a reduction in machine stoppages, enhancing efficiency without sacrificing the flexibility that is their core competitive advantage.

- ZiprPrint (Edmonton, AB): Faced with the challenge that no commercial 3D printer could effectively bond soft and hard materials in a single process, this university spin-off developed its own solution. Their novel single-nozzle system uses a "zipper-like" mechanical interlocking technique that increases bonding strength by over 40%. The technology has opened up new multi-material printing possibilities, and the company is now collaborating with research centers to produce high-value products like sensor-integrated prosthetics.

- Innovative Automation (Barrie, ON): As a provider of custom robotic solutions, this company recognized that the high capital cost of automation was a primary barrier for its own SME customers. In response, they piloted an innovative business model: instead of simply selling equipment, they actively help their clients secure the funding needed to invest in it. This approach transforms the relationship into a collaborative partnership, directly tackling a key barrier to technology adoption and enabling the modernization of their entire customer base.

It can be done - SME's can make the investment, focus on innovation, and achieve results.

Moving Forward: From Barbell to Balanced Growth

The 'barbell economy' in manufacturing presents a formidable challenge, creating a deep and widening chasm between a few technologically advanced giants and a vast number of small and medium-sized enterprises.

The barriers of capital, skills, and strategic capacity are real and deeply entrenched across North America and Europe.

However, these obstacles are not insurmountable. It means accepting reality, focusing on innovation, understanding the trends, aligning with them, and starting to work with them. The fact is, the path forward for SMEs is not to replicate the resource-intensive models of their larger counterparts.

Instead, the opportunity lies in leveraging their inherent advantage: agility. Small organizations can act faster, work faster, and adapt faster.

And it also means collaborating more - stepping outside one's own shell to access other resources. The most successful SMEs are those that recognize they cannot go it alone. By actively participating in collaborative ecosystems, SMEs can access the critical funding, talent, and expertise necessary to compete on a global scale.

Bottom line? The Fourth Industrial Revolution is not a threat to be feared, but an unprecedented opportunity to redefine the rules of success and drive the next wave of innovation and economic growth.

Futurist Jim Carroll believes that many manufacturing organizations need to spend more time manufacturing their future and less time fretting about their inability to get there.