"We are moving beyond static objects to a world of living materials that heal, think, and reshape our reality." - Futurist Jim Carroll

(Futurist Jim Carroll is writing a series on 30 Megatrends, which he first outlined in his book Dancing in the Rain: How Bold Leaders Grow Stronger in Stormy Times. The trends were shared in the book as a way of demonstrating that, despite any period of economic volatility, there is always long-term opportunity to be found. The book is now in print - learn more at dancing.jimcarroll.com)

We are experiencing unprecedented innovation in physical materials, everything from self-healing surfaces to programmable matter. These new substances enable product capabilities that were previously impossible."

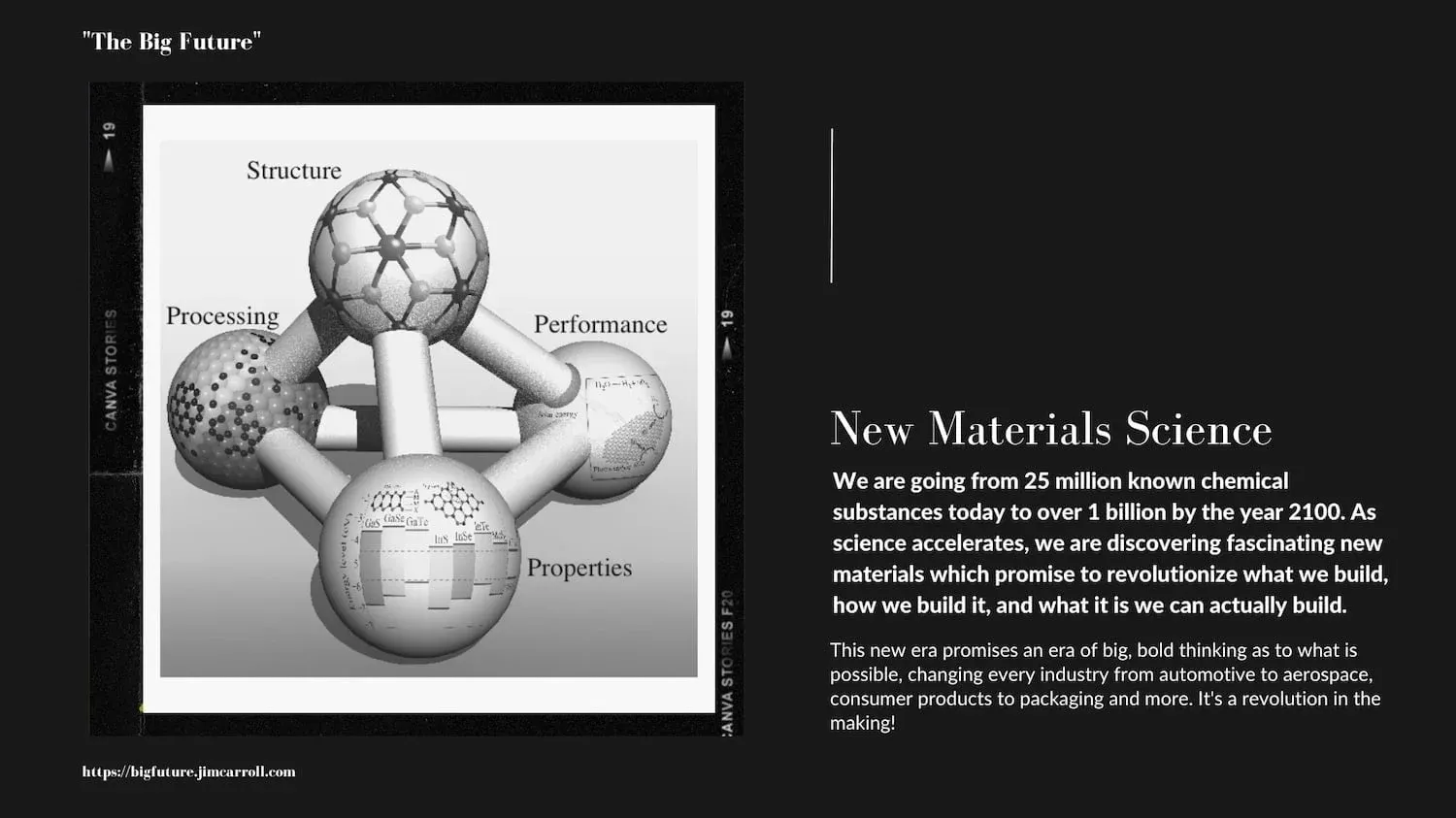

I previously covered this megatrend in my "Big Future" series, which I ran a few years ago - you'll find the whole series over at - where else! - bigfuture.jimcarroll.com.

One of the trends I covered in that series involved "new materials science," and there is a lengthy blog post worth exploring.

To get a sense of this megatrend, read what I wrote back then:

We all use materials. We never really think about it too much, though: the science behind their discovery, the acceleration of that science, and what it leads to in terms of new opportunities. That’s what this post is about – and it’s part of my BIG Future series.

Materials? Chemistry? As a futurist, my mind was opened up back in 2004 as I was preparing for a talk for an environmental government ministry. Somewhere during my research, I came across two fascinating observations as to how fast the world of chemical science was evolving.

First, I obtained from a chemical journal on the rapid evolution of knowledge/data in that field:

- To be up-to-date in all areas of chemistry, you would currently have to read about 2,000 new publications every day

- If you prefer to screen only the short abstracts, you must read 200 pages per day or about 70,000 pages per year.

- Furthermore, since the number of chemistry publications also increases exponentially, you need to double your reading capacity within the next 15 years.

- You must read 20 publications every day to grasp only 1% of the overall chemical publications!

I then found a research document that suggested that the result of this rate of advance is a rather exponential increase in the number of known chemical substances:

- “…The number of known chemical substances has been growing exponentially since 1800, from some hundreds then to about 19 million today….”

- “…. the number constantly doubles every 13 years….”

- by 2025: 80 million chemical substances

- by 2050: 300 million

- and by 2100: 5 billion……

19 billion known chemical substances to 5 billion? That’s a pretty exponential change…

Why? Consider this – it was the discovery of a single new chemical substance that led to the opportunity for Apple to miniaturize the hard drive, which led to the first iPod, many years ago. This was the birth of a multi-billion-dollar market.

For every new chemical substance, similar massive new opportunities exist. That’s what it means to live in an exponential world! And that is what it means to focus on future opportunities through innovation.

I went on:

But why is it important? Virtually every single industry, new product discovery, and invention is the result of materials science. Our faster discovery of new materials and new science leads us to:

- High-performing batteries for next-generation energy storage

- lightweight materials for more efficient and energy-saving transportation

- New electrical and optical material for the continued acceleration of digital technologies, improving the ability to meet our sustainability goals around energy, climate, and the environment

- The acceleration of biomaterial science, particularly related to the big trend of regenerative medicine, explained earlier in this series

- The development of thin solar cells that generate more energy at a lower cost

- healthcare applications such as smart wound dressing not only protect the skin but also help to heal it with controlled drug release

- technology that combines the advantages of glass and plastic without the potential disadvantages they may present for use in medical devices such as syringes, vials, blood collection devices, and tubes

The list goes on. Essentially, this aspect of science affects virtually every industry – power and telecommunications, aerospace, construction, biomedical, energy, healthcare, automotive, and sustainable development. Even the acceleration of brain science, in that new materials might help lower the risk of infection for new probes that might be used in brain surgery, and the acceleration of computer-to-brain technology

No doubt, material science is a megatrend!

What's fascinating is how, within this trend, a field of 'self-healing surfaces' and 'programmable matter' is coming about. Let's dig in! As always, there's a PDF of the full report right here.

Let's start with the idea of 'self-healing surfaces.' There's a major shift in materials science underway, which is seeing passive structural components become active participants in their maintenance. The best way to understand this is to get an industry-by-industry overview of what's up.

Consider aerospace & defense applications:

- Impact Mitigation: Ionomer-based polymers that instantaneously self-heal after high-velocity projectile punctures

- Structural Composites: Self-healing polymer matrix composites for aircraft structures

- Protective Coatings: Self-healing coatings to prevent corrosion on lightweight alloys

There are huge opportunities in the automotive industry:

- Scratch-Resistant Coatings. Transparent topcoats for automotive paint that can heal minor scratches and scuffs over time, often activated by the heat from sunlight. KRICT has demonstrated a coating that repairs itself in 30 minutes in the sun.

- Self-Healing Tires. Tires with an inner liner made of a soft, sticky self-healing polymer. If punctured, the liner automatically flows into and seals the hole, preventing air loss and allowing the driver to continue safely.

- Structural Components. Lamborghini and MIT explored incorporating microvascular networks into carbon fiber composite chassis components, allowing them to "bleed" healing resin into cracks to repair structural damage.

How about a few construction applications?

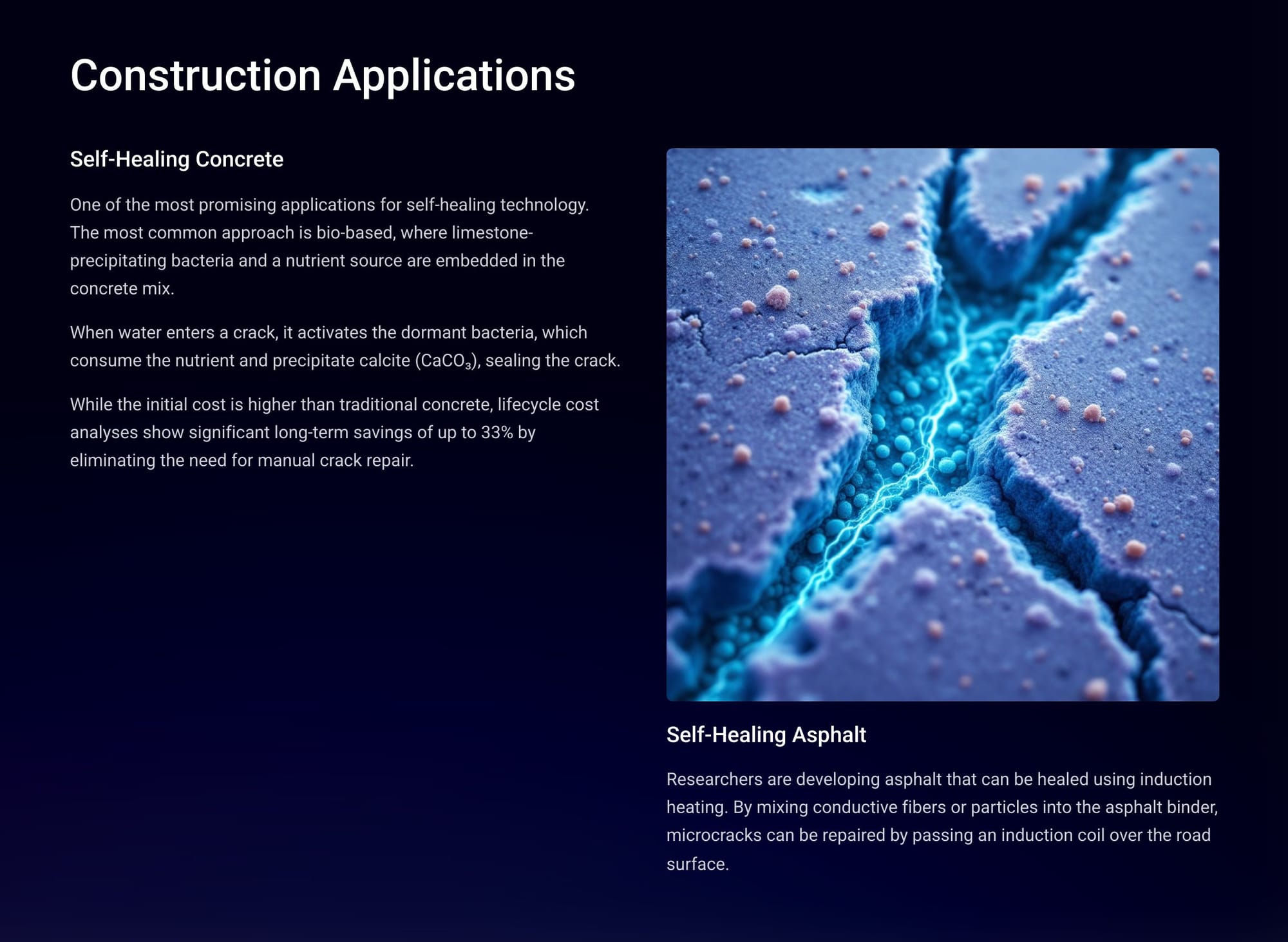

- Self-Healing Concrete. One of the most promising applications for self-healing technology. The most common approach is bio-based, where limestone-precipitating bacteria and a nutrient source are embedded in the concrete mix. When water enters a crack, it activates the dormant bacteria, which consume the nutrients and precipitate calcite, sealing the crack. While the initial cost is higher than traditional concrete, lifecycle cost analyses show significant long-term savings of up to 33% by eliminating the need for manual crack repair.

- Self-Healing Asphalt. Researchers are developing asphalt that can be healed using induction heating. By mixing conductive fibers or particles into the asphalt binder, microcracks can be repaired by passing an induction coil over the road surface.

Or healthcare & biomedical opportunities?

- Wound Care and Tissue Engineering. Self-healing hydrogels can mimic the properties of natural tissue and can be engineered to be injectable, allowing them to fill irregularly shaped wounds. They can be loaded with drugs or growth factors and used as scaffolds for tissue engineering.

- Durable Medical Devices and Implants. Self-healing polymers and composites can create more durable and long-lasting prosthetics, dental composites, and orthopedic implants, reducing the need for costly and invasive replacement surgeries.

- Flexible and Wearable Electronics. Self-healing conductive polymers are critical for wearable health sensors and "electronic skin." These devices are constantly subjected to stretching and flexing, which can cause microcracks in the conductive pathways.

Those are the aspects of material science that are already here and evolving quickly.

Things become interesting once you dive into what is called "the advent of malleable reality," which involves "programmable matter." While self-healing materials react to damage to restore a fixed state, programmable matter represents a far more radical concept: materials whose fundamental physical properties can be actively and reversibly changed on command.

Programmable matter is defined by the idea that the material itself is a computer—an ensemble of elements that inherently performs information processing to alter its bulk physical characteristics.

- First formally articulated in 1991 by Toffoli and Margolus, who envisioned a computing substrate composed of fine-grained computational nodes arranged in space. The convergence of advances in semiconductor technology, nanotechnology, robotics, and self-assembly is now making it possible to fabricate physical ensembles that can be programmed to change their properties.

- Information is Physical. Based on physicist Rolf Landauer's insight that "information is physical." The programmable matter community inverts this concept: If computation is a physical process, then physical processes can be controlled and directed by computation.

- Convergence of Hardware and Software. Programmable matter represents a fundamental convergence of hardware and software at the most basic material level. Its final form or function is not pre-determined but is an emergent result of a distributed computation performed by its constituent parts.

There's some wild stuff happening here with some fascinating ideas. Let's consider just one field, involving robotics and manufacturing applications. People are envisioning:

- Shape-Shifting Robots. Programmable matter could enable truly versatile robots that adapt their form to their environment or task. A single robot could reconfigure itself to walk on legs across rough terrain, roll as a ball for speed on flat surfaces, and then morph into a multi-limbed gripper. This is particularly revolutionary for soft robotics, where adaptable stiffness and shape are paramount.

- Rapid Prototyping and Haptic Interfaces. In industrial design, programmable matter offers the ultimate interactive modeling tool. Designers could work with a physical 'claytronic' model that they can physically push, pull, and sculpt, with changes instantly reflected in the digital design file. This provides a level of tangible, haptic feedback that is impossible with current methods, potentially accelerating the design cycle.

In the field of medical and healthcare applications, there are similarly 'wild' ideas, involving such things as:

- Minimally Invasive Surgery. A tiny robotic device could be introduced into the body through a small incision or blood vessel. Once at the target site, it could reconfigure itself into a larger, more complex tool to perform a precise operation, before collapsing back for extraction. This would drastically reduce patient trauma and recovery time.

- Smart Medical Devices and Implants. A prosthetic limb could change its stiffness and grip pattern on the fly. A smart bandage could be programmed to release different drugs in response to biological signals from the wound. Biocompatible, piezoelectric materials made from peptide-plastic hybrids could lead to sticker-like implants that sense biological signals and provide therapeutic stimulation.

Or take the field of consumer electronics and architecture:

- Transformative Devices. A single device could function as a smartphone, then expand its screen to become a tablet, and finally wrap around the wrist to become a wearable device. Clothing could become a dynamic display, with fabrics that change their color, pattern, and texture.

- Adaptive Environments. Interior walls could move and reconfigure themselves to create larger or smaller spaces on demand. Furniture could emerge from the floor when needed and retract when not in use, creating highly flexible and efficient living and working environments.

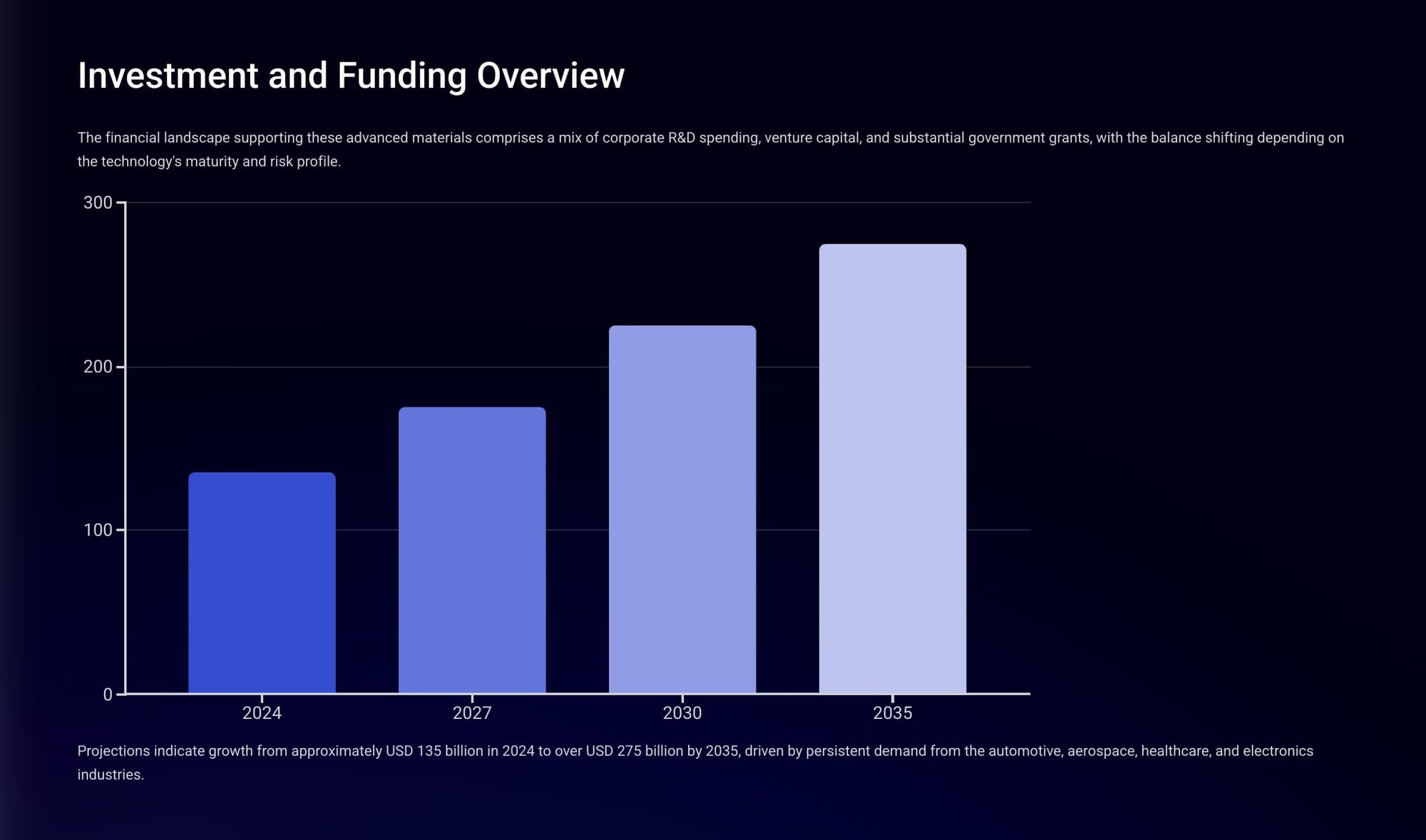

Much of this is new and full of conjecture. But the financial landscape supporting these advanced materials - both the first realistic category and the new research category - comprises a mix of corporate R&D spending, venture capital, and substantial government grants, with the balance shifting depending on the technology's maturity and risk profile.

Projections indicate growth from approximately USD 135 billion in 2024 to over USD 275 billion by 2035, driven by persistent demand from the automotive, aerospace, healthcare, and electronics industries!

The interesting thing about material science as a megatrend is that it might have the most profound implications and yet is often little noticed and rarely covered. That is set to change as some of the most dramatic and far-reaching ideas become a reality!

Futurist Jim Carroll first shared the ideas in this post with an opening keynote for the American Chemical Society in 2006. At that time, the ideas were considered to be too much like science fiction to have any real opportunity.