"With a digital twin, we don't just envision the future; we build it, test it, and perfect it, long before it ever touches the real world." - Futurist Jim Carroll

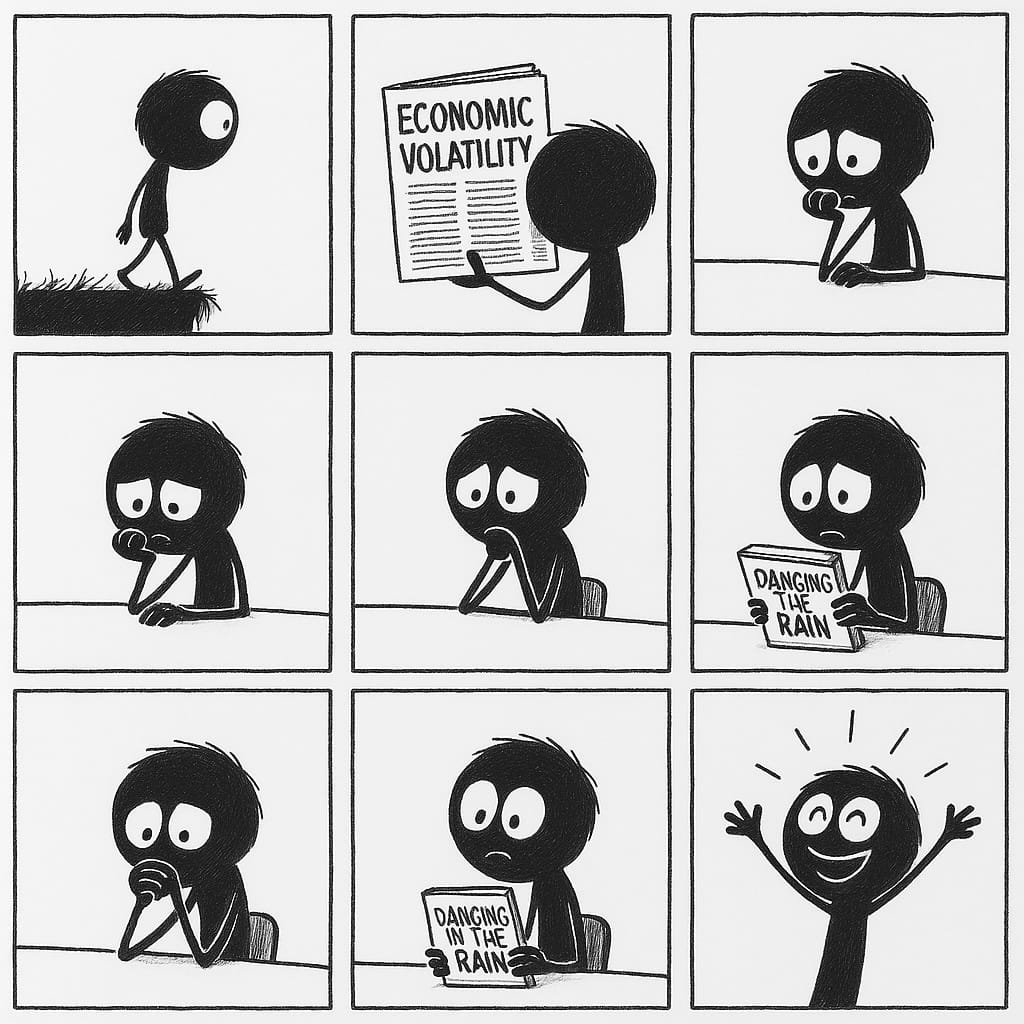

Just as an aside, I'm getting some real-world data in from folks who have bought and received the first copies of Dancing in The Rain. You should have serious FOMO. Cure it by getting your copy at dancing.jimcarroll.com. Not sure yet? Get the FREE sample chapters at sample.dancing.jimcarroll.com

Need more convincing? Here's how these 3 books I've done this year go together:

Now back to our regularly scheduled megatrends!

Let's talk about digital twins! It's one of the most unappreciated but most powerful megatrends with a huge amount of potential. And you might not know it, but it's already being used all around you.

What's it all about? Think of it this way - it involves the creation of virtual replicas that allow for unprecedented simulation, optimization, and predictive capability, involving things like supply chains, buildings, manufacturing processes, and even surgery. in essence, we can figure things out before committing to doing those things. In that way, we can solve previously impossible problems, by testing and simulating them first.

Imagine being able to test out a big, expensive idea without actually building anything. Or fixing a problem in your factory before it even happens. Sounds like science fiction, right? It's not. It's happening right now, and it's changing how businesses operate. Grab this PDF.

What exactly Is a digital twin?

Think of it as a super-detailed virtual copy of something real. This "something" could be almost anything: a factory machine, an entire building, a complex supply chain, or even, as the quote suggests, a human organ. This isn't just a static picture, though. This digital replica is constantly updated with data from its real-world counterpart. So, if a machine in your factory starts to heat up, its digital twin knows it too, in real-time.

Digital twin technology is already being used in supply chains, building management and design, manufacturing and more.

Supply Chains? Imagine a company that needs to get products from factories to customers all over the world. A digital twin of their supply chain can simulate different routes, unexpected delays, and even natural disasters to find the most efficient and resilient way to operate. They can literally "figure things out before committing to doing those things."

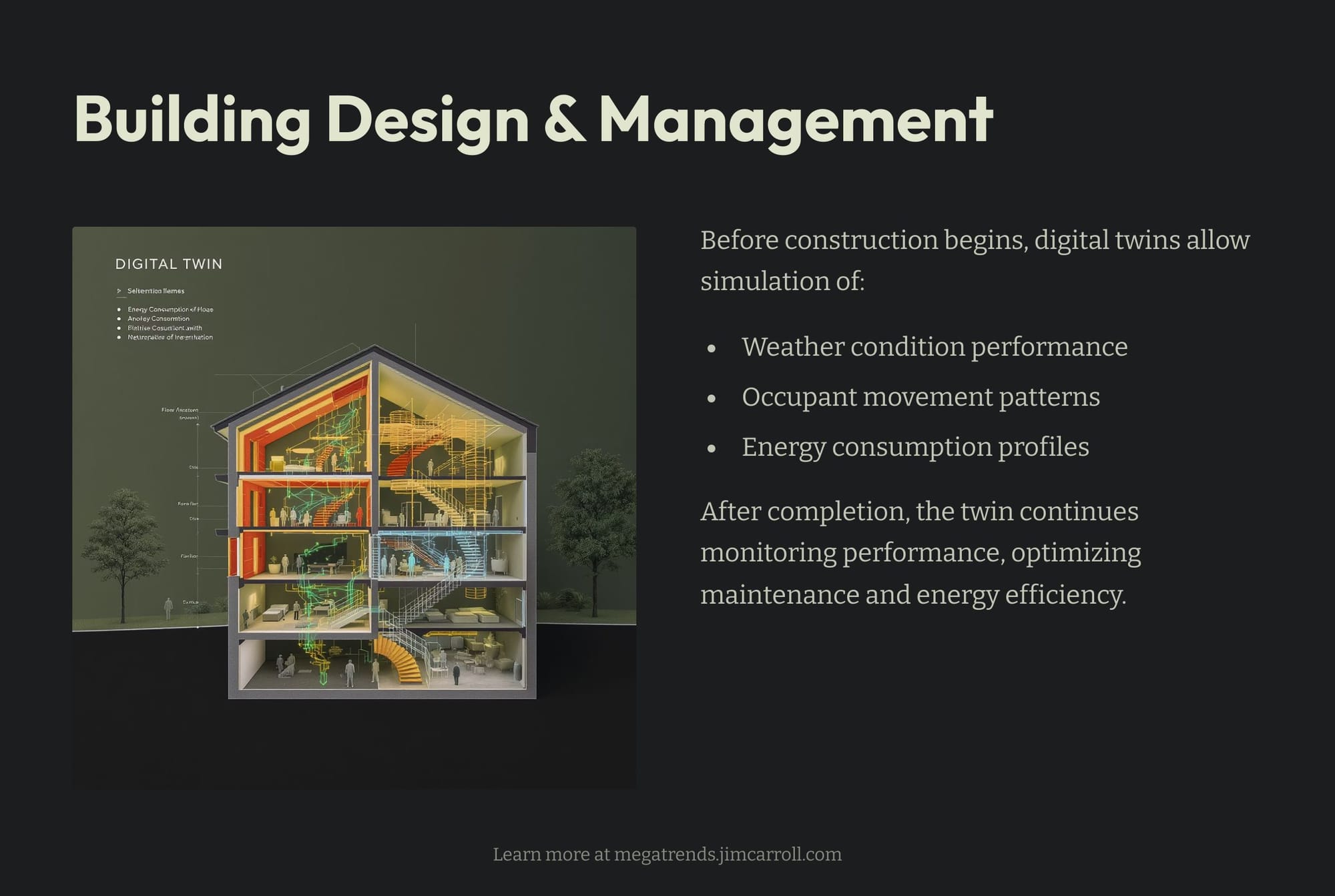

Designing and managing buildings? Before a single brick is laid, architects and engineers can create a digital twin of a new building. They can simulate how it will perform in different weather conditions, how people will move through it, and even how energy will be consumed. Once the building is built, the digital twin can continue to monitor its performance, helping with maintenance and energy efficiency.

Or manufacturing? In factories, digital twins of machines can predict when a part might fail, allowing for proactive maintenance and preventing costly downtime. They can also be used to test out new manufacturing processes virtually, ensuring they work perfectly before being implemented in the real world.

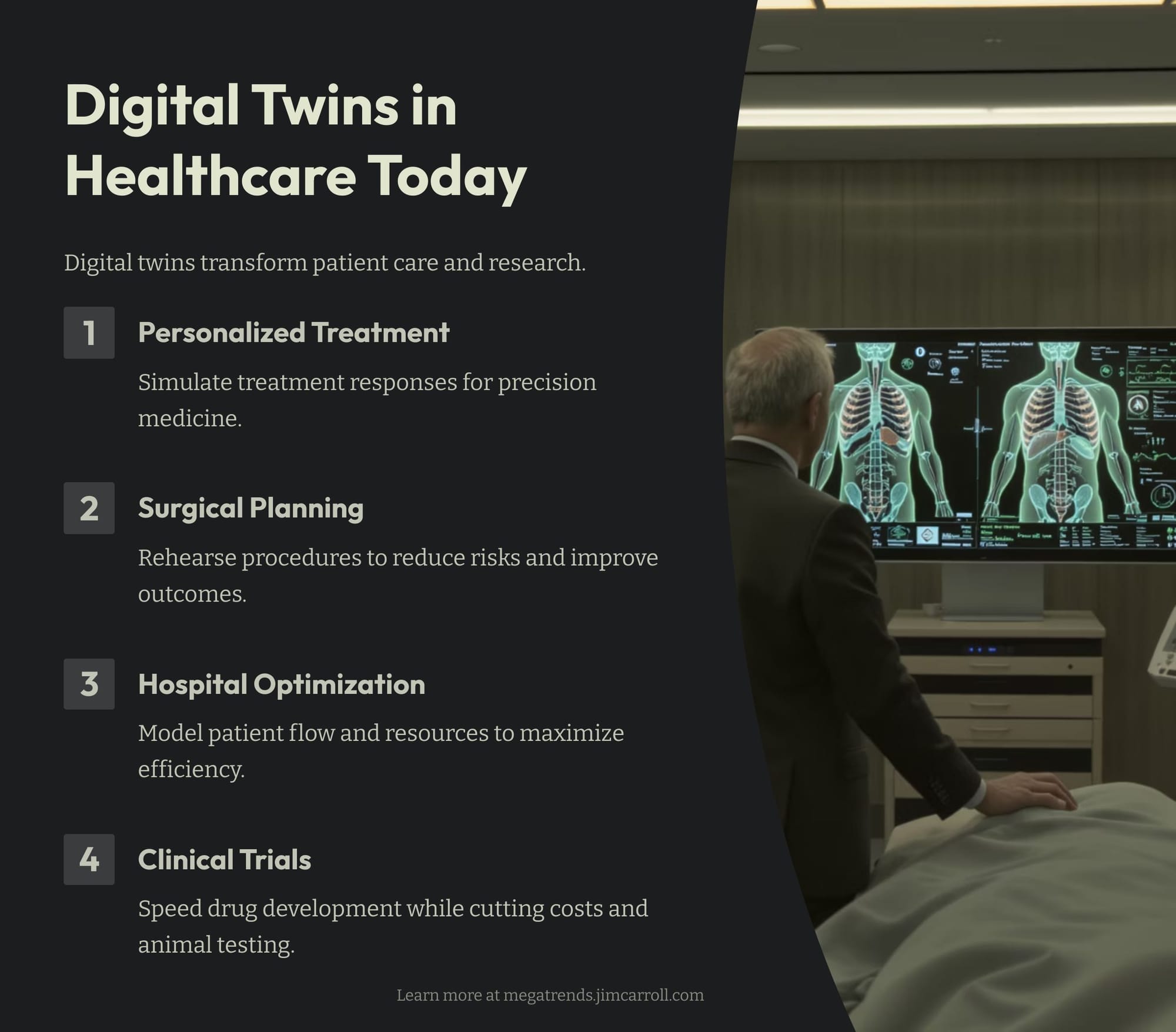

Not to forget healthcare. We can simulate healthcare solutions, plan surgeries, or virtually manage patient flow.

What's next? Advancements with personalized healthcare. Digital twins of human organs could allow doctors to test out different treatments for a patient's specific condition virtually, predicting the best course of action without any risk to the patient. Entire cities could have digital twins, allowing urban planners to simulate the impact of new infrastructure projects, traffic patterns, and even climate change scenarios. And digital twins could even be used to plan and optimize missions in space, simulating complex maneuvers and potential issues before they ever happen.

Why does it matter? Because it gives us unprecedented simulation, optimization, and predictive capability. It's like having a crystal ball for your business or your project. By understanding how things will behave before we make big investments or take significant risks.

In essence, digital twinning allows us to learn, adapt, and improve at a once unimaginable speed. It's not just a technological fad; it's a fundamental shift in how we approach problem-solving and innovation in an increasingly complex world.

Oh, and one more thing.

This stuff is not theoretical. My oldest son is a UAV Practice Manager for a major firm and a GIS / geospatial mapping expert. In a proud dad moment, here's an article he just wrote on digital twin technology in the industry in which he works.

TECHNOLOGY DATA CAPTURE AND MODEL BUILDING

BY WILLIE CARROLL

Here's a great PDF Summary of his article.

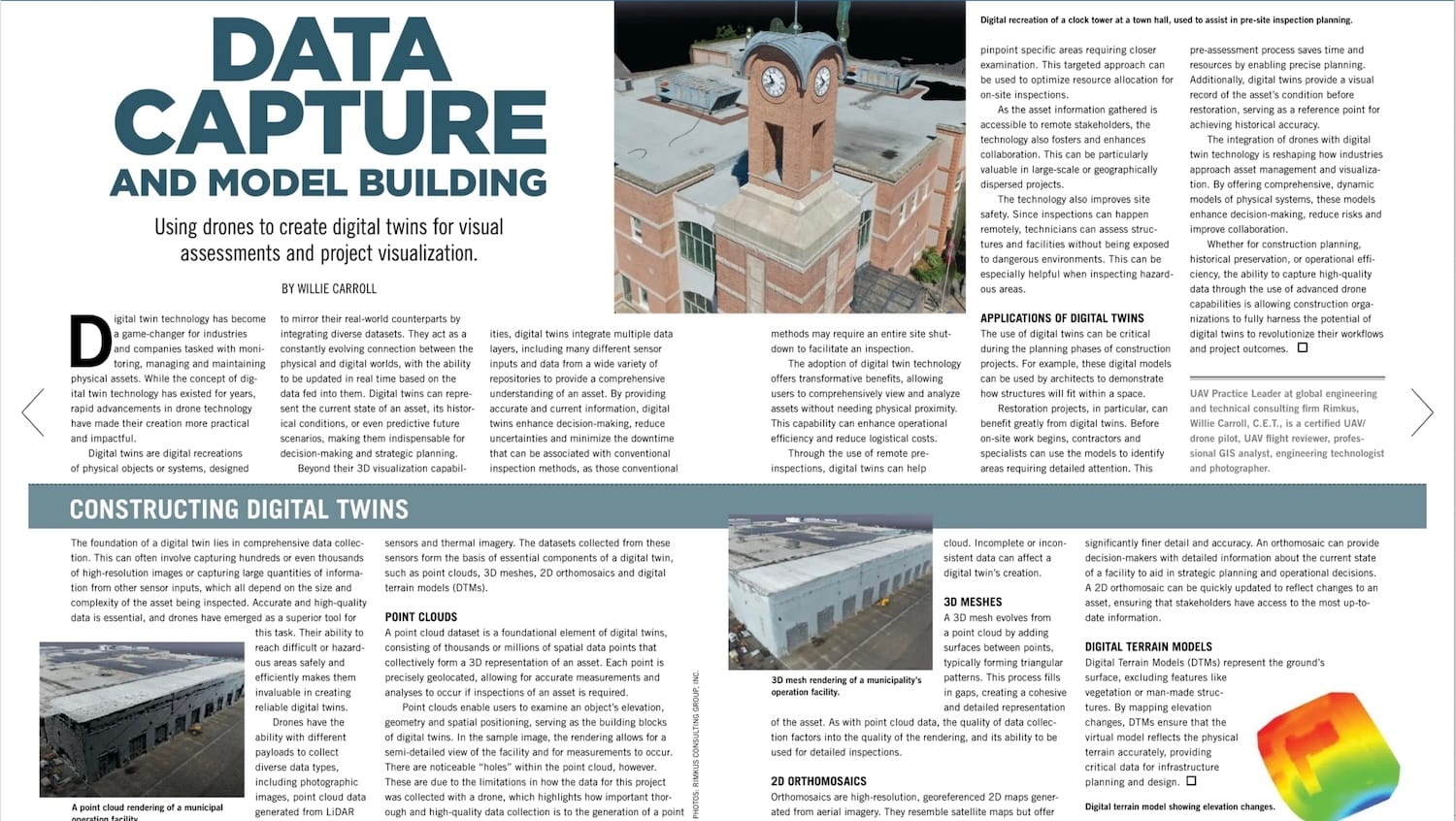

Using drones to create digital twins for visual assessments and project visualization.

Digital twin technology has become a game-changer for industries and companies tasked with monitoring, managing and maintaining physical assets. While the concept of digital twin technology has existed for years, rapid advancements in drone technology have made their creation more practical and impactful.

Digital twins are digital recreations of physical objects or systems, designed to mirror their real-world counterparts by integrating diverse datasets. They act as a constantly evolving connection between the physical and digital worlds, with the ability to be updated in real time based on the data fed into them. Digital twins can represent the current state of an asset, its historical conditions, or even predictive future scenarios, making them indispensable for decision-making and strategic planning.

CONSTRUCTING DIGITAL TWINS

The foundation of a digital twin lies in comprehensive data collection. This can often involve capturing hundreds or even thousands of high-resolution images or capturing large quantities of information from other sensor inputs, which all depend on the size and complexity of the asset being inspected. Accurate and high-quality data is essential, and drones have emerged as a superior tool for this task. Their ability to reach difficult or hazardous areas safely and efficiently makes them invaluable in creating reliable digital twins.

Drones have the ability with different payloads to collect diverse data types, including photographic images, point cloud data generated from LIDAR sensors and thermal imagery. The datasets collected from these sensors form the basis of essential components of a digital twin, such as point clouds, 3D meshes, 2D orthomosaics and digital terrain models (DTMs).

Beyond their 3D visualization capabilities, digital twins integrate multiple data layers, including many different sensor inputs and data from a wide variety of repositories to provide a comprehensive understanding of an asset. By providing accurate and current information, digital twins enhance decision-making, reduce uncertainties and minimize the downtime that can be associated with conventional inspection methods, as those conventional methods may require an entire site shut-down to facilitate an inspection.

POINT CLOUDS

A point cloud dataset is a foundational element of digital twins, consisting of thousands or millions of spatial data points that collectively form a 3D representation of an asset. Each point is precisely geolocated, allowing for accurate measurements and analyses to occur if inspections of an asset is required. Point clouds enable users to examine an object's elevation geometry and spatial positioning, serving as the building blocks of digital twins. In the sample image, the rendering allows for a semi-detailed view of the facility and for measurements to occur. There are noticeable "holes" within the point cloud, however. These are due to the limitations in how the data for this project was collected with a drone, which highlights how important thorough and high-quality data collection is to the generation of a point cloud. Incomplete or inconsistent data can affect a digital twin's creation.

The adoption of digital twin technology offers transformative benefits, allowing users to comprehensively view and analyze assets without needing physical proximity. This capability can enhance operational efficiency and reduce logistical costs. Through the use of remote pre-inspections, digital twins can help pinpoint specific areas requiring closer examination. This targeted approach can be used to optimize resource allocation for on-site inspections.

As the asset information gathered is accessible to remote stakeholders, the technology also fosters and enhances collaboration. This can be particularly valuable in large-scale or geographically dispersed projects.

The technology also improves site safety. Since inspections can happen remotely, technicians can assess structures and facilities without being exposed to dangerous environments. This can be especially helpful when inspecting hazardous areas.

APPLICATIONS OF DIGITAL TWINS

The use of digital twins can be critical during the planning phases of construction projects. For example, these digital models can be used by architects to demonstrate how structures will fit within a space.

Restoration projects, in particular, can benefit greatly from digital twins. Before on-site work begins, contractors and specialists can use the models to identify areas requiring detailed attention. This pre-assessment process saves time and resources by enabling precise planning. Additionally, digital twins provide a visual record of the asset's condition before restoration, serving as a reference point for achieving historical accuracy.

The integration of drones with digital twin technology is reshaping how industries approach asset management and visualization. By offering comprehensive, dynamic models of physical systems, these models enhance decision-making, reduce risks and improve collaboration. Whether for construction planning, historical preservation, or operational efficiency, the ability to capture high-quality data through the use of advanced drone capabilities is allowing construction organizations to fully harness the potential of digital twins to revolutionize their workflows and project outcomes.

Background:

3D MESHES

A 3D mesh evolves from a point cloud by adding surfaces between points, typically forming triangular patterns. This process fills in gaps, creating a cohesive and detailed representation of the asset. As with point cloud data, the quality of data collection factors into the quality of the rendering, and its ability to be used for detailed inspections.

2D ORTHOMOSAICS

Orthomosaics are high-resolution, georeferenced 2D maps generated from aerial imagery. They resemble satellite maps but offer significantly finer detail and accuracy. An orthomosaic can provide decision-makers with detailed information about the current state of a facility to aid in strategic planning and operational decisions. A 2D orthomosaic can be quickly updated to reflect changes to an asset, ensuring that stakeholders have access to the most up-to-date information.

DIGITAL TERRAIN MODELS

Digital Terrain Models (DTMs) represent the ground's surface, excluding features like vegetation or man-made structures. By mapping elevation changes, DTMs ensure that the virtual model reflects the physical terrain accurately, providing critical data for infrastructure planning and design.

Willie Carroll, C.E.T., is a certified UAV/drone pilot, UAV flight reviewer, professional GIS analyst, engineering technologist and photographer, and UAV Practice Leader at global engineering and technical consulting firm Rimkus.

Futurist Jim Carroll has long predicted that many children would work in jobs or careers that do not yet exist. His son's career as a drone pilot/digital twin expert is living proof of that prediction.