"If you keep tiptoeing around the truth, the lies will eventually consume you!" - Futurist Jim Carroll

This post is not some personal validation or moral high ground type of thing.

It's about the fact that U.S. manufacturing - and, well, pretty much every US industry- is at a crossroads. Between yesterday and tomorrow, opportunity and challenge, success and failure.

Throughout the weekend, I saw numerous videos online about folks who are now complaining about the state of the economy in the US. There was one in particular that seemed to be widely shared - a news report featuring numerous farmers in Arkansas complaining of the likelihood of bankruptcy because, well, costs were going up, global markets were being closed, labor was becoming scarcer (I wonder why), and more. There were other videos involving other industries, including manufacturing.

Well, here we are!

So let's just take on manufacturing as but one industry in this fascinating new reality that really never needed to happen. It seems that lots of folks are learning that certain choices lead to certain outcomes, which many long suggested would be inevitable. The problem here is that folks bought into the lies - that a few simple edicts would restore a once great industrial sector to greatness - and that there wouldn't need to be any hard work to get to where the industry is going.

Like I've long said, it doesn't work that way. You need to put in the effort.

The fact is, the United States manufacturing sector (and most other sectors) stands at a critical juncture in 2025, caught between the imperative to reinvent itself for a technology-driven future and severe headwinds from volatile, protectionist policies that suggest that such reinvention and hard work aren't necessary. I decided to take on what happens when folks buy into the lies, using all the material I've written about the sector over the years (found in the manufacturing category of my blog), with where we are today. If you want a good overview of what's necessary in the new world of manufacturing, go through a few posts in that category.

The big question is whether U.S. manufacturing is "hitting the mark" against the blueprint for 21st-century success. Read the full PDF here.

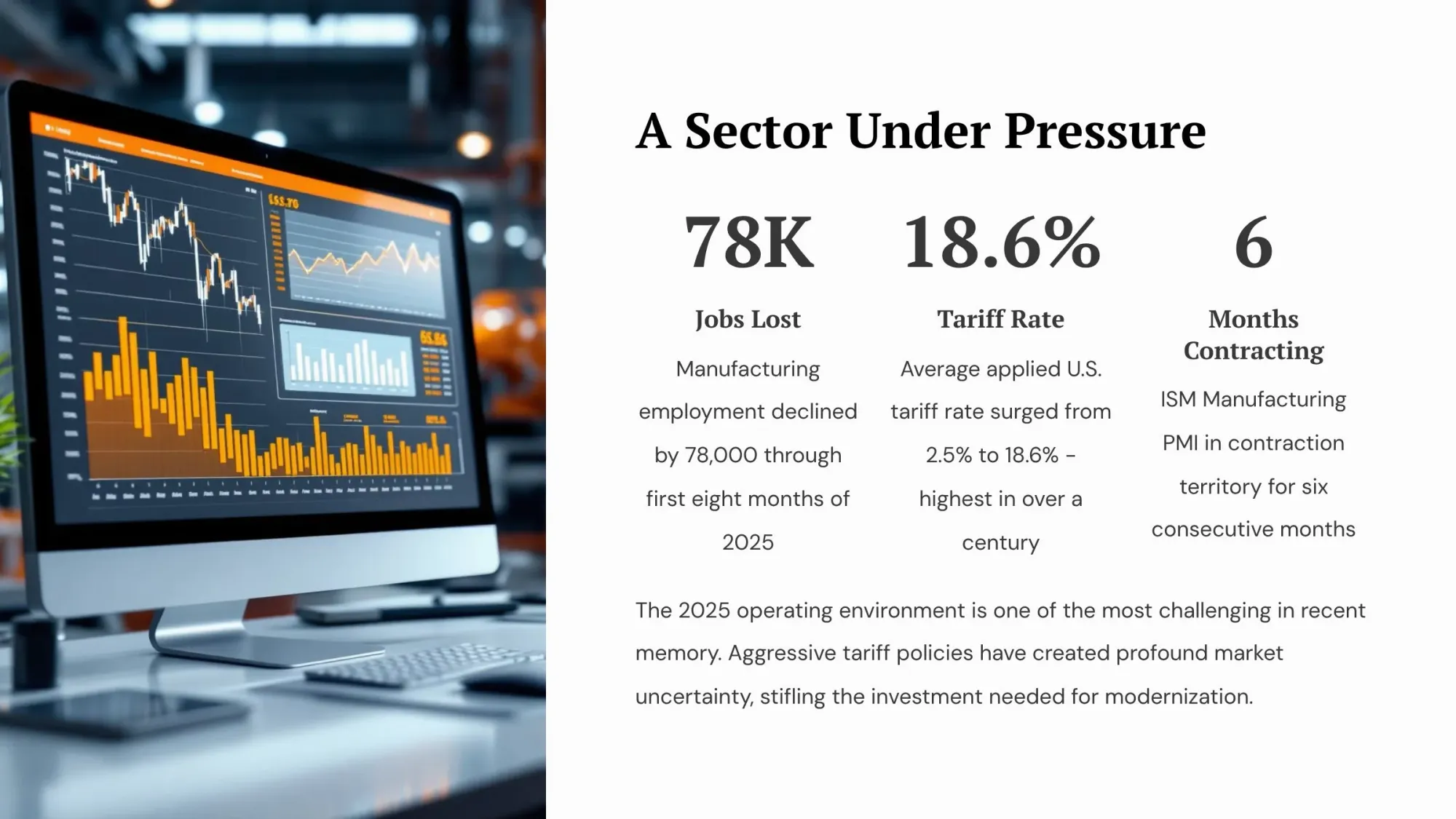

And the answer is - no. The 2025 operating environment is one of the most challenging in recent memory. Aggressive tariff policies have created profound market uncertainty, stifling the investment needed for modernization. Consider some facts.

- 78,000 Jobs Lost: Manufacturing employment declined by 78,000 through the first eight months of 2025.

- 18.6% Tariff Rate: The average applied U.S. tariff rate surged from 2.5% to 18.6%, the highest in over a century.

- 6 Months Contracting: The ISM Manufacturing PMI has been in contraction territory for six consecutive months.

For over three decades, I've advised global manufacturers on a critical message: the sector must reorient from crisis management to seizing massive opportunities - and to do so, it must align with the massive reinvention that is coming from technology. All that involves what a lot of folks call Industry 4.0, aka The Smart Factory Revolution

The smart factory represents the fusion of physical and digital worlds through cyber-physical systems, fundamentally transforming how products are designed, made, and delivered.

- Industrial IoT: Interconnected machines and systems enable real-time data exchange and seamless collaboration across production processes.

- AI & Analytics: Big Data analytics and machine learning generate predictive insights for maintenance, quality control, and supply chain optimization.

- Advanced Robotics: Collaborative robots work alongside humans, augmenting their capabilities and freeing workers for complex problem-solving tasks.

- Additive Manufacturing: 3D printing enables rapid prototyping, complex geometries, on-demand spare parts, and mass customization.

All of this involves significant investment - in skills and knowledge, automation and equipment, training and learning. It takes hard work.

The problem is, folks are being sold a pack of lies that all that needs to happen is that a few walls need to go up. In that reality, how is the US doing so far? I used Google Gemini to take a look at these issues and do a bit of a grade on where things stand. Is U.S. manufacturing hitting the mark?

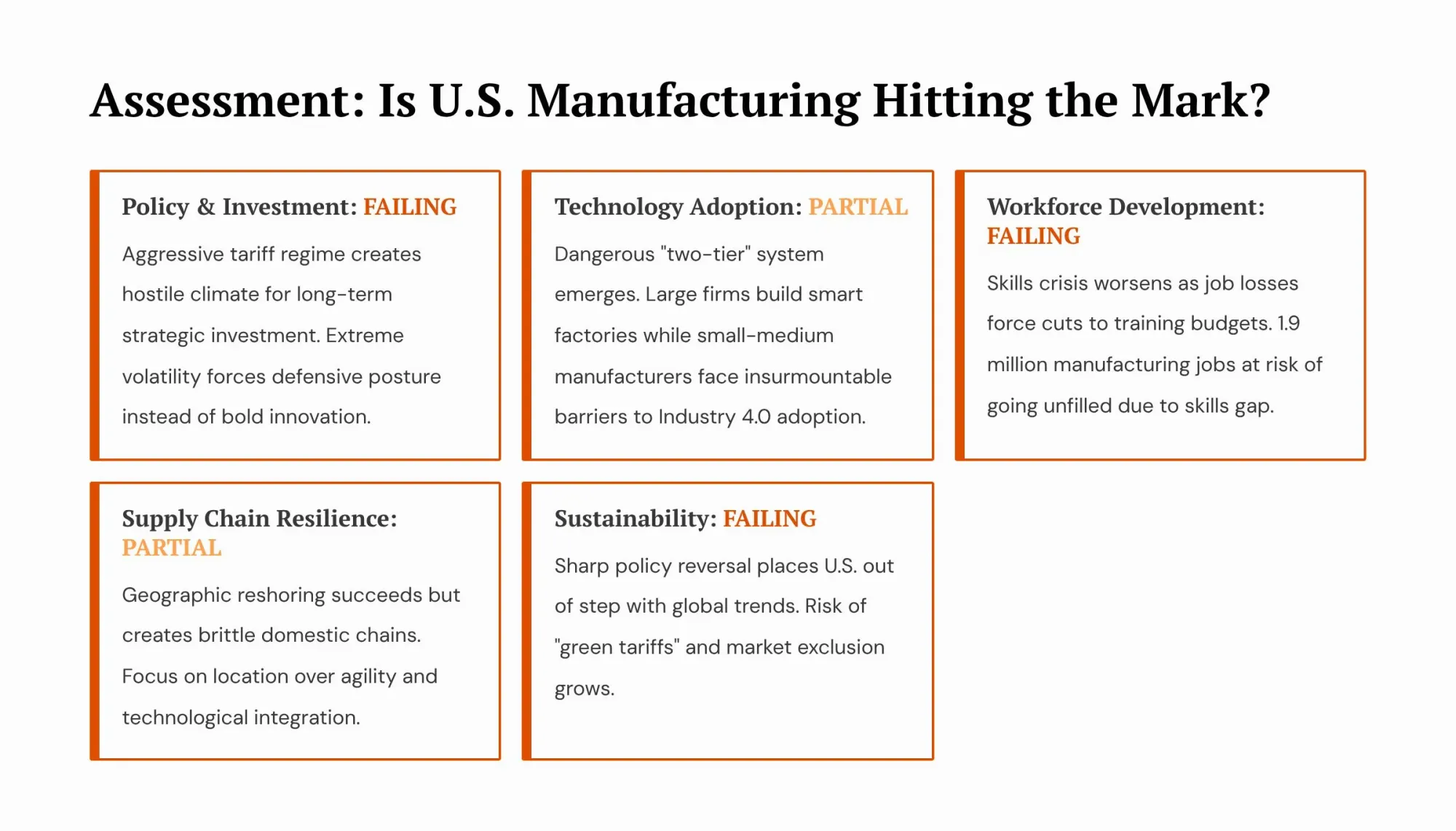

- Policy & Investment: FAILING. The aggressive tariff regime creates a hostile climate for long-term strategic investment. Extreme volatility forces a defensive posture instead of bold innovation.

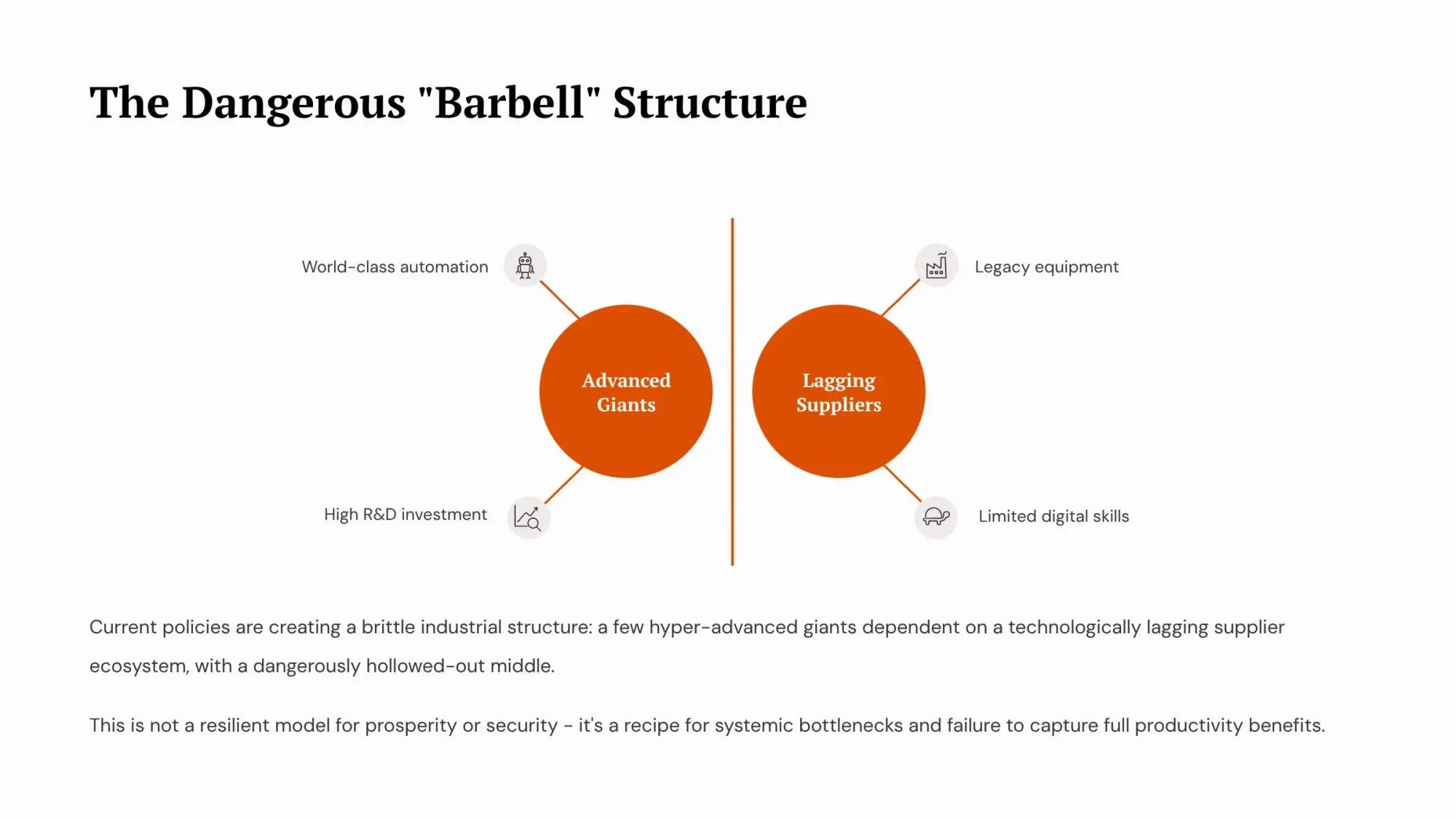

- Technology Adoption: PARTIAL. A dangerous "two-tier" system is emerging. Large firms are building smart factories while small- and medium-sized manufacturers face insurmountable barriers to Industry 4.0 adoption.

- Workforce Development: FAILING. The skills crisis is worsening as job losses force cuts to training budgets. An estimated 1.9 million manufacturing jobs are at risk of going unfilled due to the skills gap.

- Supply Chain Resilience: PARTIAL. Geographic reshoring has succeeded but creates brittle domestic chains. The focus is on location over agility and technological integration.

- Sustainability: FAILING. A sharp policy reversal places the U.S. out of step with global trends. The risk of "green tariffs" and market exclusion is growing. You can't sell into a green Europe if you aren't fitting into their green schemes. Reality.

And the sad thing is, there is a bit of a 'barbell structure' in place. Big manufacturing organizations are making the necessary investments; small and medium-sized ones, the backbone of the sector, are NOT. This is not a resilient model for prosperity or security—it's a recipe for systemic bottlenecks and a failure to capture full productivity benefits.

So what needs to happen? To be blunt, stop letting the lies define your actions. Success demands a strategic focus on the fundamentals: speed, agility, talent, and technology. It might not be too late.

If you want to dig into this topic in a bit more depth, I've got a full 40-page report right here.

Things don't seem so great right now, and unless things turn around, they will likely get worse in this sector (and many others). I don't want to come across as sanctimonious, but none of this really needed to happen. But here we are - it's not too late.

But when people buy into the lies and refuse to adapt to reality, reality always bites back and comes to consume them.

Futurist Jim Carroll is pretty saddened by the state of affairs in most industries today.